What’s inside:

Bill only trunk stock inventory is frequently used in both emergency and elective surgeries.

Also known as field stock or trunk stock, they arrive directly into the point of care and are selected by the surgeon for immediate use.

This paper covers:

- The impact of bill-only items not appearing on the item master

- Why trunk stock is an administrative burden on busy nurses

- Existing workarounds for recording vendor-owned items

- The risk on non-documentation of trunk stock

- The cost of trunk stock

- Charge capture of bill-only items

What happens when unexpected supplies arrive straight into the procedure room?

Getting inventory management right comes down to monitoring each individual product as it flows through the hospital inventory supply chain. All too often these trunk stock inventory items remain invisible in hospital systems and ultimately this compromises patient safety and results in missed revenue.

With so much at stake, let’s take a closer look at the issue of trunk stock inventory and review best practice in capturing these non-stock items in the operating room and procedural room.

When is Trunk Stock Inventory used?

The most common entry point of trunk stock into the hospital or surgery center is during complex cases, such as orthopedic procedures and neurological procedures. These rely heavily on trunk stock inventory, as physicians cannot anticipate all the products and item sizes they will need.

Trunk stock may include items that come in different sizes, or that are specialist devices or implants used for specific clinical circumstances. But it’s not just regular stock items that end up being brought in directly to the procedure room, vendors often introduce new implants and trial products to physicians and suggest that these are used to solve the medical issue at hand.

Trunk stock is often considered to be a safety net, ensuring that the physician is covered for inventory whatever clinical situation he may find himself in.

But it’s a double-edged sword – protecting from one side while adding risks from the other.

While trunk stock is surgeon-endorsed, with clear clinical gains, administratively it presents a challenge.

The perils of not being on the hospital’s item master list

The Item Master is king in inventory management, driving the whole supply chain process. Each item entered into the system at the POU then has its SKU checked against the item list, and once matched, the supply chain flows.

But trunk stock inventory presents off-contract and non-file data issues.

It does not appear on the Item Master and has no prior data trail.

It may be a trial item, a non-stock item or a different size or batch of an item that is currently out of stock.

In any of these cases, attempts to scan the item at the point of use will result in an error. Items included in orthopedic kits and sets, as well as small consumables such as screws, are known to be particularly problematic to capture.

Trunk stock is a burden on busy nurses

In procedure rooms, the circulatory nurse is purely concerned with supporting the clinical team and the patient, so non-nursing tasks such as supply chain administration are not a priority.

In fact, it’s been reported that 52% of items used in surgery are not recorded or charged.

We hold regular discussions with perioperative nurses who confirm it’s a big issue:

“There was almost a unanimous agreement that those items were not being captured or recorded, particularly because they were not on the item master.”

At the point of care very few people know about the trunk item – just the vendor rep, the surgeon, the scrub and the circulating nurse. All are aware that non-capture of consumed items is a procedural violation, and it falls on busy perioperative nurses to bring the item into compliance. Despite the importance of this task, the truth is that information gaps often prevent these items from being recorded in the system during the surgery.

The reality is that dealing with the electronic capture of trunk stock is just too problematic and time consuming. These items are routinely left uncaptured at the point of use.

What’s really needed is a quick and easy method to capture trunk stock inventory during surgery, without manual data entry or longwinded admin.

Current workarounds to make trunk stock inventory visible

As there is no quick fix during surgery, adding undocumented items into the system, or fixing data errors or gaps becomes a post-surgery task. There are two common workarounds: one with the perioperative nurse leading and the other with the back office being left to backtrack.

Nurse workaround 1 – Getting an item listed before entering on to the EHR:

When items don’t scan into the system and an error message displays on the screen, one option is for nurses to input the item as a ‘one time entry’.

This task involves keying in all the pertinent data and will result in the system accepting the item… but for ONE time only.

So next time the same item is scanned, it will again come up with an error message – making this workaround a temporary fix, with no long-term benefits.

Nurse workaround 2 – Getting an item listed before entering on to the EHR:

In order to get a non-listed item on to the hospital item master, the circulatory nurse needs to take the packaging to the Materials Management team so that it can be entered into their system.

Once entered the nurse will then have to go back into the EHR to manually enter the information into the patient’s chart.

This process cannot be done between surgeries, so the nurse will have to add this to the tasks at the end of her shift. Trunk stock may have been consumed during several procedures, so the post-surgery admin builds up and adds non nursing tasks to an already long and stressful workday. All too often, something more urgent comes up and the admin task slips by the wayside, leaving the items unrecorded.

Back-office workaround – getting a non-listed item on to the EHR:

The back-office workaround relies upon the vendor’s invoice reaching the OR General Business Manager. They need to get the item on to the hospital system, and then digitally associate it with the patient and procedure. The charge and invoice details will also need to be recorded.

When product SKUs from trunk stock does not appear on the Item Master, the process for updating the EHR is clumsy and convoluted for. It involves a series of screens, drop downs and data entry – it’s a manual, clunky, error-prone process.

Three different workarounds with the same result

Whichever way the hospital tries to deal with capturing trunk stock, clunky workarounds mean that there is a high big risk of it not getting recorded at all or being documented with data gaps or errors due to keying in mistakes or omissions.

It’s clear that capturing supply utilization during surgery would be the ideal option, as there is no quick and simple workaround.

Failure to capture trunk items has serious implications, let’s take a look at these.

The risks of non-captured trunk stock inventory

Patient safety and Compliance

Trunk stock goes from the vendor’s hands to the surgeon and is then implanted into the patient, all in quick succession. There is a lack of clarity over responsibility.

Who checks if the product has expired or was recalled prior to usage?

And if the item was not captured on the EHR, what happens if there is a subsequent product recall? How can the patient be quickly identified and contacted?

The sad fact is that UDI data is not routinely collected on trunk stock and many items are used unchecked, these are red flags for patient safety plus a potential non-compliance for clinicians and the organization.

Trunk stock inventory is risky all around and many hospitals are seeking solutions that lower these risks.

It’s clear that capturing items at the point of care, and making product safety checks prior to consumption, can prevent never events and is the model to aim for.

Capturing item usage at the point of care – Snap&Go by IDENTI Medical

Inventory Management

In order for Materials Management staff to accurately manage supplies for elective surgeries and to anticipate upcoming inventory requirements, supply chain data on historical usage is needed.

As trunk stock is routinely left outside of data-capture, there is a whole set of data that is invisible and cannot be factored into inventory planning.

This serves to create a viscous circle, whereby the same items will continue to appear as trunk stock only, as there was no record of it in the supply chain to prompt reorder.

Expiry management of these items also falls into no man’s land and remains outside of the hospital’s stock control activities.

For inventory management systems to work well, accurate forecasting and stock predictions based on accurate consumptions data is necessary. This data is then used to make predictions, assess demand and generally help the organization move towards a balanced inventory.

When trunk stock is missed off the records, there’s a hole in the data and complete lack of visibility of the full range of items consumed.

The cost of trunk stock inventory

Trunk stock may be convenient, but this last-minute inventory is charged at a premium, digging deep into the inventory budget.

As we’ve stated, it can be seen that by trunk stock remaining invisible, the cost of managing the hospital inventory is high, there’s a:

- Lack of accurate data to practice demand-driven procurement, resulting in overstocking or stockouts

- Perpetuation of reliance on bill-only items when there’s no visible history to review

- Persistent inability to understand utilization patterns for more accurate future-planning

- Dependence on a procurement method with inflated costs, exacerbate by difficulties identifying products that are regularly purchased as bill-only, but where it would be beneficial to include these in the vendor contract to take advantageo price discounts.

Filling in the trunk stock data gaps would give the hospital far better control of their inventory, enable demand-driven restocking, and data-driven decisions to be made.

Charge Capture of trunk stock inventory

Let’s talk money!

Trunk stock tends to be high value chargeable items. The very items you really need to capture.

In a complex spinal case, the surgeon may use 100+ products and just 5% of these may be trunk stock. But these items may relate to 35% of the cost of surgery. It’s a big hole if it’s not captured.

Lack of item and charge capture on the EHR, leads to trunk stock being missed off billing and case reimbursement falling short.

Trunk stock costs money – both in terms of it being a last-minute item and then, to add insult to injury, being absent from billing reconciliation.

With trunk stock throwing a curve ball on inventory management processes, it’s time to look at how to avoid the pitfalls and figure out the best solution to handling these bill-only items.

How to capture trunk stock in surgery

At IDENTI Medical we find the gaps in hospital workflows and develop tools to bridge these gaps and strengthen the chain.

It is clear that the lack of a data record means that trunk stock becomes a slippery item and falls through system cracks.

Barcode scanning and direct data entry are ineffective, so we have developed a failsafe way to capture all items at the point of care, including tricky trunk stock.

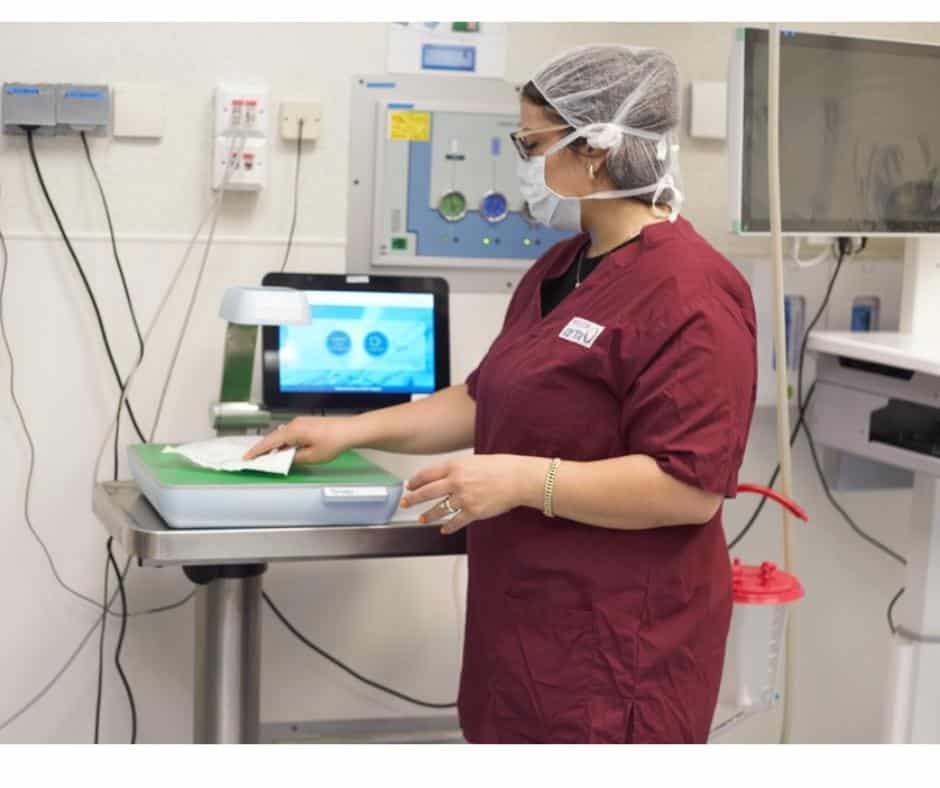

We use image recognition and AI technology to capture all product information and digitally record this on the EHR in real time. Our system also flags up recall and expiry issues in seconds, so clinicians can be assured that all items are safe before usage.

Snap & Go provides 100% item and charge capture, including trunk stock inventory not on the item list.

Our clever technology can also digitally capture manually completed implant sheets in just a few seconds.

Looking for a trunk stock inventory management solution?

Snap & Go is your all-round solution to trunk stock inventory – bringing it onto hospital systems in real time, providing pre-consumption safety checks and ensuring billing reconciliation – for every consumed item, including bill-only products.