UDI Management

Using AI to deliver full UDI data capture at the point of care

Let AI vision enhance your EHR records with UDI tracking for full compliance and accuracy.

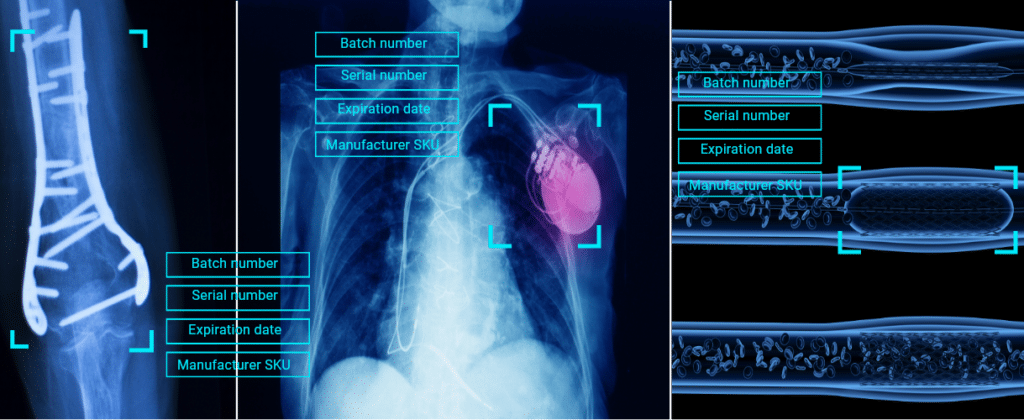

Precision UDI tracking delivers implant transparency and traceability.

Yet all too often technology fails to fully monitor this high value inventory, leading to inefficient inventory management, and putting both UDI compliance and patients at risk.

In today’s digital era, capturing UDI at the point of care demands an Automatic Identification Data Capture (AIDC) tool. However, many hospitals still rely on traditional systems that struggle to handle the complex variety of medical inventory, particularly the surgical items flowing through operating rooms and procedural rooms.

Capturing and recording the UDI data of every high-value item consumed in surgery is a difficult task. Common UDI management and data capture challenges include barcode readability issues, the collection of partial data only, dynamic coding changes to the GTIN resulting in item master mismatches and failed scans, bill-only, off-contract and substitute items that aren’t ‘in the system,’ and lengthy manual workarounds with a high risk of UDI data errors and omissions. Traditional tech has failed, and providers are looking towards next-generation technology for a better UDI management solution. New image recognition, AI, and machine learning technology have finally cracked UDI documentation, enabling 100% reporting and full UDI capture, sent straight to the EHR, ERP, and MMIS.

Be recall-ready. Plug UDI data gaps and prevent inputting errors, with a fully automated process that safeguards patients.

No need to preload. Make sure full UDI details of ‘bill-only’ and ‘off contract’ items are recorded, despite not being in the system.

Liberate perioperative nurses from time-consuming manual workarounds and fixes that take them away from patient care.

Documentation audit?

Be UDI compliant in a single “Snap”!

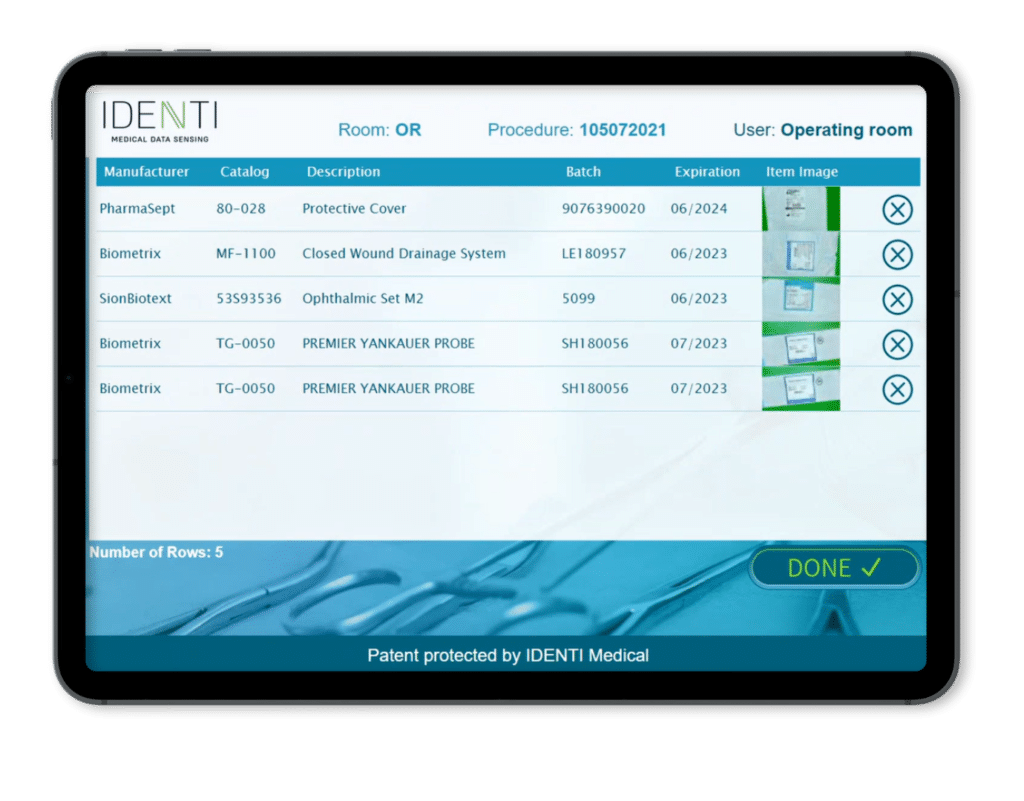

Next-Gen data capture: Snap&Go uses image recognition and AI technology to seamlessly capture full product information at the point of use, including SKU, batch number, serial/lot, expiry date and more.

30-40% reduction in Peri-Op admin: Nurses simply place the item under the computer vision sensor, wait for the green light to flash (in just 3 seconds) and can then rest assured that full UDI details will be electrically recorded in the electronic health record.

Automated item validation: Access to a globally-populated SKU database ensures every item is verified, whether its listed in your local item master or not.

Auto corrections: AI technology and machine learning algorithms support data-fixing and gap-filling, so that every item has a correct, standardized UDI entry.

When you use the right technology, UDI management is seamlessly incorporated into perioperative workflows and is a fully automated process.

IDENTIs automated UDI management technology ensures full regulatory and audit compliance.

How does IDENTI UDI Tracker improve your perioperative processes?

IDENTI’s UDI Tracker system streamlines OR workflows by enhancing your system’s capability to read and interpret UDI barcodes on consumed implants, reducing the time spent by nurses on documenting supply usage at the point of care. Select the technology that suits your set-up and requirements. Two ways to enjoy single-scan UDI tracking with IDENTI’s UDI Tracking system.

Data Sharing

“EHR-Ready” data is sent to your system, eg. EPIC, Cerner

Data Processing

The IDENTIPlatform extracts the information from the UDI data string

Data Validation

Data validation via the IDENTIPlatform

Data Capture Method

Option 1: EMR/EHR Standalone

Option 2: IDENTI Reporting Station

Compliance – ensure audit-proof documentation and full regulatory compliance

Reduced admin: Release nurses from time-consuming data-entry with a fully automated process.

Recalls – quickly discover which patients have been effected by a product or batch recall.

The benefits of using Snap&Go for UDI management at the point of use

Discover our Implant Management Bundle

The comprehensive solution for UDI Management – personalize to each sub page.

Gaining full oversight of your implants requires the tracking of both stock levels and consumption. Our AI-powered implant management solution optimizes your data collection capabilities, giving you the full picture you need for smarter implant management.

Use cloud AI tech to build trust and transparency between supply chain partners, through shared data.

AI vision : the image to data revolution

Existing point-of-use systems are inadequate when it comes to UDI management and routinely result in incomplete and non-compliant patient records. – which is a big risk to patient safety and compliance.

Snap & Go is custom-made for the surgical setting and uses patented image recognition and AI technology to fully automate surgical supply utilization.

Futuristic computer vision “reads” product packages, labels, and even hand-written implant sheets, ensuring complete and correct UDI implant details in your patient records – no gaps, no errors.

New technology boosts patient safety with 100% automated UDI capture and full medical device traceability. It’s time to join the image-to-data revolution.

TOTALSENSE

RFID for hospitals : full inventory transparency

UHF RFID Cabinet and Mobile Hand Scanner – for the management of tagged medical devices, tissue and implant.

- Real-time, item-level visibility and control.

- Digital, UDI-compliant stock records.

- Effective expiry management.

- Automated, data-driven restocks.

- Inventory metrics, reports and insights

Perpetual stock monitoring and dynamic data keeps you up to date with inventory levels and steers management decisions.