What’s inside:

Thousands of non-sterile orthopedic implants are used every day, yet point-of-use data capture methods struggle to document these items.

This article takes a look at:

- Why medical devices and implants require UDI tracking

- The challenge of data capture in the surgery setting

- The issues that make non-sterile orthopedic implants difficult to document

- How computer vision and AI technology are now being used to document non-sterile orthopedic implants

Medical device tracking

Medical devices and implants are required to be tracked throughout their life cycle, in accordance with FDA UDI regulations. UDI tracking ensures the visibility of implants from the point of manufacture through to usage. When an implant is used in surgery a digital link needs to be made between the patient and product so that, should any recall occur, the patient is easily tracked and traced.

The 2019 Allergan breast implant recall was a wakeup call for the healthcare industry and highlighted the role UDI implant tracking plays in preventing ‘never events’ in healthcare.

But UDI tracking is not as simple as it seems, and there are various problems associated with the different methods used for UDI device tracking in the surgical setting.

The point of care is known to have its own unique challenges, with many hospitals and surgery centers struggling to achieve full utilization data using the point of use data capture tools at hand. Most will have long-winded, manual work-arounds to deal with POU scanning failures, and many will also have post-surgical documentation audits in place as a final safety check.

Automatic tracking of orthopedic implants and medical devices used in surgery

While many hospitals and ASCs have issues with POU utilization and charge capture during surgery, there is one particular type of stock that causes widespread problems, whichever data capture method is used at the point of care.

The issue that all surgical data capture methods struggle with, is non-sterile orthopedic surgical medical supplies.

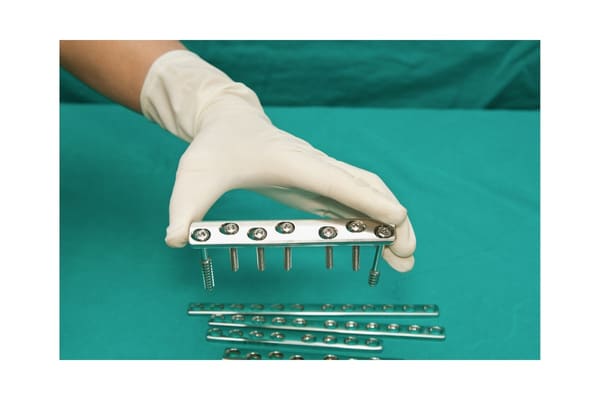

These orthopedic items are usually small implants such as nuts, bolts, screws and plates which are received in a non-sterile state and then go through the hospital sterilization unit prior to usage.

The difficulty in documenting non-sterile implants

Tracking healthcare inventory kits and sets is problematic because the packaging, that contains the UDI barcode, is removed for sterilization and the items arrive in the procedure room on a sterilized tray.

In 2016 GS1 in Healthcare in the US convened the Orthopedic Implant Workgroup on this issue, and recognized the complexities involved in charting non-sterile orthopedic items. They urged the health-tech industry to come up with better solutions that ensured full and accurate UDI management and tracking.

Manufacturers have tried to find solutions for this issue, but it remains a labor-intensive process with opportunities for errors and omissions.

Image recognition and AI technology – the solution to orthopedic item capture during surgery

Using existing technology and methods just doesn’t seem to solve the issue, it’s time to think outside of the box.

‘Snap & Go’ is a groundbreaking POU data capture tool that uses computer vision and AI technology to identify and document all items used in surgery.

No more scanning or data entry. The Circulating Nurse just needs to take a quick ‘snap’ of product packaging and the cloud inventory systems does the rest.

‘Snap & Go’s AI management system is connected to a global SKU database and is able to identify items based on the data it obtained from the product packaging.

Sounds great, but how does this help non-sterile orthopedic implants?

‘Snap & Go’ is able to ‘read’ hand-written Implant Sheets too!

The nurse simply needs to take a ‘snap’ of a completed, hand-written Implant Sheet and our POU data capture technology is able to interpret this, identify the items and document the individual products and quantities used in the EMR, ERP and MMIS.

‘Snap & Go’ can digitalize hand-written Implant Sheets.

Tracking small, non-sterile implants just got simpler!

See our infographic ‘Digitalize the Implant Sheet‘ which shows how ‘Snap & Go’ allows nurses to continue manually logging usage on an Implant Sheet which is then digitalized at the end of surgery.

Contact us to find out how ‘Snap & Go’ can improve orthopedic point of use data capture.

See a video of Snap & Go in action