In recent years the Kanban and PAR systems used to manage hospital supplies have become increasingly advanced, and modern upgrades are often driven by sophisticated management software.

Inventory management used to be based on best guesses. Not anymore!

The most advanced Kanban and PAR inventory systems for hospitals now include automated supplies restocking and data insights, ensuring that the inventory management process is streamlined and efficient.

This article looks at the benefit of automated Kanban and PAR systems and highlights the dashboard metrics and data insights that a good system can provide.

The difference between Kanban Inventory Control and the PAR system?

‘Kanban and PAR’ are often cited in the same breath but are in fact two different inventory management methods.

- PAR solutions are based around maintaining a set quantity of supplies in each bin and ensuring ‘PAR supply levels’ are maintained.

- Kanban solutions are based on usage – ensuring replenishment occurs when a pre-set minimum level is reached. This system commonly uses two bins.

Kanban and PAR storage bins have gone through a revolution in recent years. While PAR systems used to be associated with manual management and counting, these days digital tags and autonomous, weight-based PAR systems are available too.

What is a hybrid Kanban inventory system?

Hybrid Kanban and PAR systems for inventory management are where a mix of both Kanban and PAR bins are used. The logistics team would need to consider the type, size and value of products, as well as their usage rate, when deciding on the best mix of Kanban and PAR bins to use. Optimum room layout and storage solutions are individual to each hospital or surgery center, and the materials management team can review the Kanban and PAR options available and decide upon the best storage methods and store room configuration for each ward.

Hybrid solutions may involve a mix of automated and manual systems that sit side by side, or alternatively there may be a fully manual or fully automated hybrid Kanban and PAR system in place.

In this image IDENTI autonomous weight-based PAR bins can be seen on the right – this is a PAR bin with inbuilt weighing scales, a digital screen and replenish themselves automatically. IDENTI has the only portable and digital weight-based PAR bin on the market – it replaces fixed, unwieldly wall units.

A Kanban system with IDENTI’s Push Button Restock Tag can be seen on the left.

Hospitals and surgery centers choose the best match Kanban and PAR mix for their supplies spaces.

Systems can work well side by side and the logistics team can monitor and review the best room configuration.

For automated PAR systems, each product needs to be associated with its own bin, the SKU will be integrated within coding on the bin label and loaded on to the software. In addition, minimum and maximum PAR levels can be set for each product.

We’re going to take a look at an example of a fully automated Kanban and PAR bin solution and investigate not just the different storage bin options that possible but also become familiar with the value that the managing software brings, in particular the Dashboard and data.

How things were – the manual process for Kanban and PAR in healthcare

Before we take a deeper look into automated Kanban and PAR hospital inventory management systems let’s remember exactly how the manual Kanban and PAR supplies management worked.

Manual Kanban and PAR systems in hospitals used to purely consist of a plastic bin and a printed label.

Ensuring stocks were maintained was an error-prone, time-consuming process that relied upon manual monitoring and reordering to keep supplies at hand.

The process of monitoring supplies included manual counts and a multitude of manual orders.

It was a burden, not just on logistics staff but also on busy nurses too.

The system was plagued by inaccuracies – Materials Managers did not have up to date information on stock or clear visibility of their hospital inventory.

Orders relied upon a ‘best guess’ and were inaccurate – so surplus stock led to crowded supplies spaces and stock outs happened all too often.

The manual Kanban and PAR ordering system, although suitable for some products, was crying out to be automated for others.

Over recent years the humble Kanban and PAR bin has evolved.

Many of the solutions on offer today provide added time, resource and cost efficiencies when compared to manual PAR and Kanban inventory management systems.

What is an automated Kanban and PAR inventory management solution?

An automated Kanban and PAR solution is one that contains both hardware (the bins) and software (the management system). Let’s take a look at both.

Kanban and PAR hardware:

When automation is added into Kanban and PAR inventory bin solutions, there are a few different options:

- pre-printed, pre-coded labels

- RFID tags that work alongside RFID boards or empty bin storage points

- barcoded labels

- digital tags

- electronic racks or walls of bins, often with in-built weighing scales

- or, new on the scene, individual automated weight-based PAR bins, with their own in-built digital label

Most automated Kanban and PAR systems use barcode readers or RFID technology to communicate with software. The collection of bin data may be via scanners, readers, smart phones or tablets or, in the case of IDENTI’s automated PAR bin, no reader is necessary at all, as the bin digitally communicates with the management system directly, via a gateway.

Kanban and PAR software:

The quality of Kanban and PAR software differs, with newer systems being more sophisticated.

Generally automated PAR software aims to:

- improve the visibility of hospital inventory and make supply chain efficiencies

- automate tracking and replenishment,

- result in more accurate ordering that reduces stock outs and surplus supplies

- helps managers gain an understanding of actual usage

- auto generates orders based on pre-set reorder points

- displays useful data such as minimum/maximum par levels, utilization and turn rates

What are the features of a good automated Kanban and PAR solution?

Advances in technology have led to improvements in both Kanban and PAR hardware and software.

A good system is:

- able to provide a hybrid solution, that optimizes store room capacity

- flexible and suitable for different shapes and sizes of supplies and room configurations

- automated, to add accuracy – removing the need for manual counts

- backed up by smart technology that can provide meaningful metrics and data insights

Modern Kanban and PAR systems need to offer all of the above to provide maximum value and impact on supply chain efficiencies.

Many Kanban and PAR models are unable to fulfil all of the criteria above, so we’d like to showcase how IDENTI Medical has combined technical know-how and healthcare sector knowledge, to develop a Kanban and PAR system that ticks all the boxes.

What time and resources can be saved by using a smart Kanban and PAR system?

What does automation mean for busy logistics and ward staff? Does it actually have an impact on the ground?

Hell yeah!

- automated Kanban and PAR takes the legwork out of inventory management.

- no more dashing from one supplies space to another by inventory clerks, undertaking one monotonous cycle count after another.

- no more manual orders based on inaccurate levels of need.

- an end to the preparation of far too many orders a week and the time-drain of repetitive order processing

- reduced order preparation and inventory refills after consolidated orders result in fewer, larger restocks based on accurate data

It’s not just empty works and heavy marketing, read on to see the results of a pilot demonstrating the value of automation.

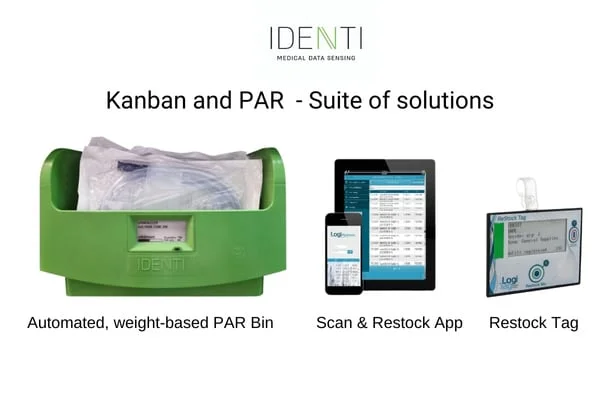

What is the IDENTI suite of Kanban and PAR solutions?

The IDENTI Medical Kanban and PAR system is an example of a fully automated Kanban and PAR suite of solutions. It was designed specifically for the hospital and surgery center setting, to improve efficiency in the management of medical supplies.

IDENTI’s products use patient-protected RFID technologies and are powered by an AI management system. The product range includes the newly launched autonomous weight-based PAR bin, Kanban Re-Stock tags and the Scan and the Restock mobile app.

This suite of medical inventory solutions caters for all types of bulk hospital supplies and provides flexible configuration options, whatever the size or shape of the storage space.

Whereas other companies expect store rooms to be organized around their big, unwieldly weight-based wall units – IDENTI offers maximum flexibility, recognizing that hospitals have limited storage space and aspire to create order in disorganized supplies spaces and increase storage capacity. IDENTI products are therefore all stand-alone – no fixed units, all solutions are based on storage in individual bins directly on your choice of shelving, so they can fit in with your existing storage infrastructure. Flexible storage solutions are combined with smart technology to provide the most accurate and efficient automation on the market, due to the sophisticated software that drives the whole inventory management system.

Feedback on the benefits of introducing a Kanban and PAR inventory solutions

Before we investigate further let’s check how the introduction of IDENTI’s Kanban and PAR solution has impacted nursing and logistics teams.

A pilot study undertaken by a customer on the introduction of IDENTIs hybrid Kanban and PAR solution found that the system:

- eliminated all nurse involvement in stock orders

- resulted in a reduction of over 50% in the time spent by logistics staff on the ward

- automated and streamlined the restock process

- reduced stock outs and surpluses

- lead to an increase in nurse satisfaction in the logistics service – from 53% to 90%

We cam see that having a smart system in place as a real impact on the ground, relieving busy nurses of logistics duties and making the hospital inventory supply chain more efficient. So let’s take a close look at IDENTI’s hospital supplies inventory solution.

What is the difference between different Kanban and PAR products?

IDENTI’s Kanban and PAR products for hospitals are suitable for different types of supplies and store room configurations.

- The Restock Tag– a digital tag for 2 bin Kanban systems that has a restock button – it just takes one click by nurses to generate an order while the second replacement bin continues to provide supplies.

- Scan and Restock App – this mobile app is a quick way to scan RFID labels plus create and monitor orders

- PAR Weighing Bins – a breakthrough product – the first wireless, self-replenishing and digital scale bin on the market – it comes in 3 sizes, has inbuilt precision scales that constantly monitor bin stock, providing real time inventory data. They sense when their stock has reached the minimum point and autonomously generate an order.

Hospitals and surgery centers can decide on the best type of solution to use and increasingly, many are choosing to put hybrid systems in place, which use a mix of them all.

The Role of Data in Automated Kanban and PAR solutions

Materials Managers recognize that accurate, real-time data is the secret to effective stock control and inventory management. The system has therefore been designed, not only to get the basics right – ie. monitoring usage and triggering restock requisitions, but also to analyze the data captured by each individual bin and compile reports, metrics and data analytics.

IDENTI’s Kanbar and PAR Dashboard

provides data insights that

steer inventory management decision making

IDENTI’s Kanban and PAR solutions can work individually or as a hybrid solution, but they all have one thing in common – connection to the IDENTI Platform.

The IDENTI Platform management system

IDENTI’s cloud-based platform is powered by artificial intelligence and machine learning. It fully integrates with ERP, EHR and MMIS systems.

The Platform accesses a global item catalog for quick product recognition and updates the hospitals item master.

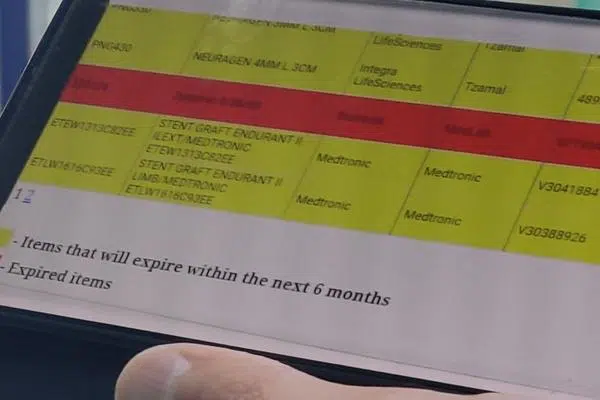

The Kanban and PAR Dashboard provides Materials Managers with key management data on the supplies stored in IDENTI Kanban and PAR bins across the hospital site.

Getting a constant feed of data is your ‘ears and eyes’ to what’s going on in your supplies spaces. It’s the Big Brother of inventory management!

Information is everything. Actionable information is a game changer. Having constant data on your full Kanban and PAR inventory, backed up by metrics, reports and data insights, gives inventory managers the vision and control that they need to effortlessly achieve a balanced inventory. Instead of your staff running around and never being able to keep on top of hospital supplies, here the system monitors and shares real-time stock levels.

So let’s see the type of data that is available on the IDENTI Platform and gain an understanding of how this can be used to improve the management of medical inventory.

Kanban and PAR Dashboard Design

The Kanban and PAR Dashboard sits on the IDENTI Platform .

IDENTI works in partnership with hospitals when setting up new Kanban and PAR solutions.

The Dashboard’s daily work screens are designed in conjunction with operating teams, displaying the data that they have highlighted as being the most useful.

The Kanban and PAR dashboard displays metrics that provide an ‘at a glance’ view of inventory.

This is real-time data, constantly being fed into by information received from the full range of hybrid products, Restock Tags, the Scan and Restock App and the autonomous Weight-Based PAR bin.

The Kanban and PAR Dashboard is interactive – with individual tiles updating in real-time, as the source data changes – giving complete and up to date visibility of the inventory.

Dashboard Reports

The Dashboard has a user-friendly interface and produces daily, easy-to-understand reports.

Kanban and PAR data reports can be set up daily, or at your desired timescale, and automatic notifications will be sent to all those staff you have identified as recipients.

Reports include (but are not limited to):

+ inventory turns

+ average days to restock

+ restock frequency

+ zero turn items

Your very own bespoke reports can be designed too, ensuring your staff have all the data they need at their fingertips!

Daily reports can be set up to steer operational activity – ensuring soon to expire items are used first, resetting PAR levels, reviewing zero turn items and more. Data ensures that you never miss a trick and stay on top of all the main issues at hand.

Dashboard Data Insights

The IDENTI Dashboard can be viewed on your computer or mobile device.

Actionable data insights shine a light on hospital inventory, identifying critical data such as usage patterns and supply chain inefficiencies, enabling Materials Managers to gain control. Historical information enables usage patterns to emerge and drives data-driven decision making.

Autonomous restocking and performance data make hospital supplies replenishment a far more accurate process than in times past.

Dashboard usage-metrics and reports that summarize data, make it easy to:

- avoid stock-outs and surpluses

- analyze trends

- make data-driven decisions

- make cost savings

- reduce waste

The data accessed through the Kanban and PAR Dashboard results in an informed Materials Management team, who can achieve and maintain a balanced inventory, based on actual consumption.

The Kanban and PAR Dashboard enables healthcare providers to gain full visibility of their inventory, resulting in a data-driven supply chain, with tighter cost control.

Hospitals using PAR systems need to set their minimum and maximum PAR levels, the problem is, without accurate usage data, knowledge of seasonal trends etc. they are basically working in the dark. This can result in bloated inventories, wasted expenditure and overcrowded store rooms. Basing PAR levels on data insights results in the logistics team ordering the correct amount of stock to meet demand.

Automated Kanban and PAR takes the legwork out of inventory management; no more counts, fewer turns and, finally, accurate data!

Interoperability of Kanban and PAR system and hospital IT infrastructure

The IDENTI Platform that acts as a managing system for all of our inventory management solutions and seamlessly interfaces with your internal systems so that all Kanban and PAR inventory levels and restocks are on your own software too.

The Hospital Inventory Supply Chain

A quick word about the hospital inventory supply chain. Since the COVID epidemic, the healthcare industry has experienced many supply chain disruptions, which have unfortunately remained as a continuing challenge.

When traditional supply routes became unreliable, hospitals needed to quickly broaden their vendor base so that they could secure supplies and achieve the best possible delivery timescales.

In order to keep pace with supply chain changes, hospital systems needed to be flexible enough to identify, log and track new SKUs that were previously not stocked. In addition, deliveries from alternative vendors contained the standard products but often in different sized packaging, which caused issues for hospitals with one size bins and fixed configuration store rooms.

Automated systems have fared better in these challenging times, as they are smarter and more adept at managing a higher volume of supplies from a broader range of vendors. The flexible store room configurations also enable the storage of a greater variety of different sized items.

Final thoughts on Kanban and PAR systems for hospitals

This article has provided an overview of the transition from manual to automated Kanban and PAR systems for healthcare. We have reflected on the traditional manual Kanban and PAR system, identifying why automation can be a better option for some products. We have also considered the benefits that automation has over manual systems in terms of visibility of medical supplies, usage tracking and restocking.

We looked at an example of new, automated systems, in particular, the IDENTI Medical hybrid Kanban and PAR solution, getting a glimpse of its managing system dashboard which sits on the IDENTI Platform. We looked at some of the metrics and data insights that the Kanban and PAR managing system provided and how this information can result in data-driven inventory management and results in a balanced inventory.

There’s lots to gain by reviewing your Kanban and PAR arrangements and utilizing technology-driven solutions that save you time, money and resources.

Find out more about IDENTI’s Kanban and PAR suite of solutions.