Kanban & PAR

Optimize Inventory & Replenishment: Automated Kanban & PAR System for Medical Supplies

Medical supply management made easy

Medical supply management has traditionally been a manual process, but as healthcare providers struggle to manage more products with fewer staff, they’re turning to technology to discover the power of automated inventory control.

There’s a real need to improve efficiency, lower costs, and reduce stockouts with automated inventory replenishment, but the automated Kanban & PAR systems on the market often rely on nurse compliance, or are large, cumbersome units that don’t suit every supply space.

So IDENTI decided to reimagine hospital supply management and design user-friendly solutions that are designed for the average healthcare provider and add speed, accuracy and automation to the management of medical supplies.

At IDENTI we think you deserve:

- A system that seamlessly slots into your current layout and configuration, without causing any disruption.

- Easy implementation, with minimum training and user-friendly automation that’s so simple to use.

- A balanced inventory that reflects demand – so that nurses always have the right supplies at hand, and managers can reduce all unnecessary costs.

Our patented, next-generation Kanban & PAR inventory management system effectively streamlines and automates your supply management workflow while generating all the data you need to make smarter supply chain decisions.

It’s time to upgrade to an automated Kanban or PAR management solution that optimizes supply chain management and supports better healthcare delivery.

Accurate!

Go from ‘best guess’ to real data

Simple!

Move from labor-intensive

to effortless supplies management

Efficient!

Put an end to stockouts and rush orders

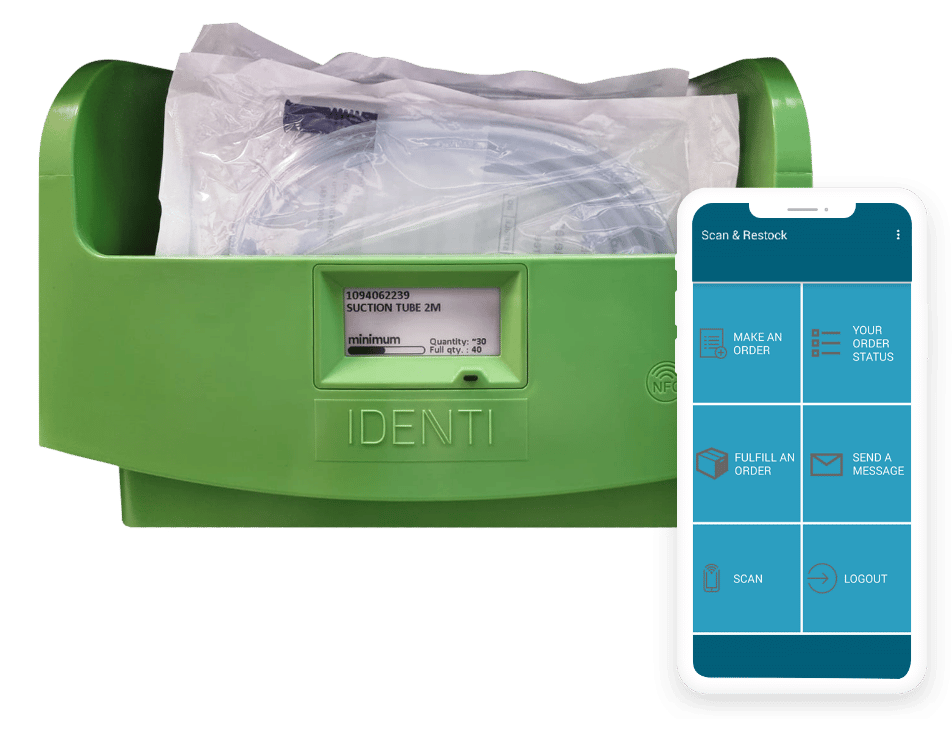

Meet IDENTI's Automated Kanban & PAR Solutions:

Gain insight into your inventory

The combination of digital hardware plus advanced software turns passive supply rooms into automated inventory hubs.

Our advanced AI-powered software takes the strain out of managing inventory by processing supply data and transforming it into meaningful business information.

IDENTI’s automated Kanban and PAR management solutions are all managed under a single AI cloud management system.

- Simple Kanban & PAR Dashboard: User-friendly interface, real-time data,

and easy-to-understand reports. - Get the full picture: Gain full inventory vision via metrics, reports, and analytics.

- Work smarter: Data-driven inventory management. Streamlined inventory, reduced labor, and lower costs.

- Seamless integration: Interoperability with hospital ERP, EHR, and MMIS.

- Transparency: Option to link to vendor ERPs for a shared vision and

increased synergy.

Reports pull complex data together into meaningful information that supports more efficient day-to-day operations and ensures managers stay a step ahead of demand with predictive analytics that highlight trends for more precise planning.

The system drives through transparency between supply chain partners so that everyone can see the real picture and practice proactive supply management.

Stop all the second-guessing and get accurate AI-generated information that has the power to transform your supply management.

CASE STUDY

Read one hospital’s journey moving from a manual medical supply management system to an automated solution.

This hospital had a manual system in place that was inefficient. Nurses spent far too long involved in supply chain tasks, and store rooms were disorganized and crowded, with regular stock outs causing frustration.

Automating the hospital’s Kanban & PAR system minimized the role of clinical staff in supplies management and ensured that accurate supply data flowed into the system. Finally, everyone involved in supply chain management was able to gain full visibility of stock levels and get a better grip on demand.

Adding automated solutions that deliver a digitally managed space ensures managers have all the data they need at their fingertips for smarter inventory management.

Find out more about our Kanban & PAR automation tools and discover how integrating autonomous bins and digital tags saved money, reduced labor and improved efficiency for this hospital.