What’s inside:

This is a case study on the introduction of a hybrid, automated kanban and par system on an inpatient ward.

We look at:

- The pitfalls of manual kanban and par and why the hospital wanted an upgrade

- The hybrid solution chosen – both kanban and par automated solutions.

- The ROI of the automated medical supply management solution.

Executive Summary

This case study outlines how Sheba Medical Center, Israel’s largest hospital, streamlined its hospital inventory management system using IDENTI’s hybrid Kanban and PAR solution.

By introducing autonomous PAR weight-based bins, digital restock tags, and a scan-and-restock app, the hospital automated reordering, improved stock accuracy, and eliminated manual supply chain duties for nursing staff.

Hospital Inventory Management Challenges

Before the study, Sheba faced common hospital inventory challenges:

- Manual reorders: Nurses and logistics staff conducted manual checks that were error-prone and time-consuming.

- Inefficient ordering: Excessive and irregular orders created high administrative workloads without maintaining a balanced inventory.

- Disorganized storerooms: Overcrowding and disorganized storage areas made supplies difficult to find and track.

- Clinical burden: Nurses were spending significant time on supply chain activities, reducing patient care hours and job satisfaction

The goal was to address these challenges by reorganizing the ward store room and introducing a smart hospital inventory management system.

Kanban and PAR Hospital Inventory Management Solution

The hospital implemented IDENTI’s Kanban and PAR hybrid hospital inventory management system, featuring three automation solutions:

- Autonomous PAR Weight-Based Bins

- Digital Restock Tags

- Scan and Restock App

All data feeds into a cloud-based hospital inventory management software that delivers real-time stock visibility, usage analytics, and reporting tools. This integration allowed the materials management team to make data-driven inventory decisions and eliminate manual reordering.

The Results of Implementation

IDENTI’s hybrid Kanban and PAR hospital inventory management system transformed the ward’s operations

- Logistics staff time on the ward dropped by over 50%

- Time spent by nurses on inventory orders was reduced to 0

- Nurse satisfaction soared from 53% to 90%

- Consolidated, data-driven restocking cut total orders by 57%, creating a more efficient, automated, and demand-driven inventory system.

Conclusion

The IDENTI Kanban and PAR solution added efficiency and automation to the logistics process. The updated hospital inventory management system resulted in significant time and resource savings. The hospital is currently looking to roll out this model to other departments.

The Full Case Study

This case study is designed to share best practices in hospital inventory management systems for hospital supplies based on Israel’s largest hospital’s attempt to remove all logistics activities from the workload of clinical staff. It showcases IDENTI’s hybrid Kanban & PAR solution the autonomous, Wireless PAR Weighing Bin.

The findings of this case study are based on a pilot conducted at Sheba Medical Center, one of the largest hospitals in Israel.

We look at how Sheba Hospital introduced a new hospital inventory management system using hybrid Kanban and PAR-level tracking to a ward and the results.

Project Goals

Sheba’s primary objective was to remove nursing staff from supply chain responsibilities while improving the efficiency of the materials management service.

The Procurement Department defined measurable success criteria:

- To reduce nursing time spent on logistics:

- Eliminate nursing time spent on supply orders (target: 0%)

- Reduce nursing time on supply organization by 85%

- To increase job satisfaction for nurses by a minimum of 90%

- To maintain a balanced inventory on wards by at least 90% (measured via stock shortage reporting).

Hospital Inventory Challenges

Sheba sought to improve supply availability on the ward while minimizing clinical staff involvement.

There were three main challenges that the hospital wanted to address:

Challenge 1: Ordering based on the experience and discretion of nursing staff

Problem: Orders generated by the Supervising Nurse or Deputy Nurse were a “best guess” decision that did not accurately reflect the need. This often resulted in inaccurate or high-frequency orders.

The hospital identified the following recurring issues:

- Managing supplies was a time-consuming burden for nursing staff, in part due to the wide range of SKUs

- Frequent stockouts and surpluses

- Nurses needed to hunt down missing supplies in other departments when they were not available from the Logistics Department.

- Irregular restock patterns and excessive orders were common

Challenge 2: Disorganized storerooms

Problem: The department suffered from crowded storerooms; issues included:

- New stock is not being checked or approved by the clinical department staff, leaving the MMIS hanging with incomplete data.

- Delays in unpacking orders caused boxes to be left outside the store room, which blocked the corridor and risked items going missing.

- The lack of inventory storage space led to items being stacked on carts in the middle of the supplies room or in inaccessible places such as top shelves.

- Nurses needed to spend excessive time searching for the items they required.

Challenge 3: Excessive nurse involvement in materials management

Problem: Busy nurses want easy access to supplies and an end to stock-outs, but they want the Logistics Team to manage this.

- They don’t want their time taken up with supply chain tasks

- Logistics tasks reduce the time available for patient care

- Materials management activities have a negative impact on nurses’ job satisfaction.

Kanban and PAR Solution

To address these challenges, Sheba implemented IDENTI’s Kanban and PAR hospital inventory management systems, which included:

- PAR Weighing Bins: Wireless, scale-based bins that automatically trigger restocks.

- Restock Tags: One-click order generation with a restock button that can generate a new order with one click

- Scan and Restock App: Mobile app to monitor, track, and manage orders

Methodology

The pilot ran for three months (March-June 2022), with the hybrid system fully active during the final seven weeks.

The pilot took place in one ward, and the methodology included data collection, staff interviews, and the mapping of processes and store rooms. This provided a benchmark to compare performance before and after the arrival of the new system.

Pilot Methodology Summary

- Data collection and analysis

- Satisfaction surveys

- Measurement of execution time

- Additional conclusions and recommendations for application in departments

Pilot Action Taken:

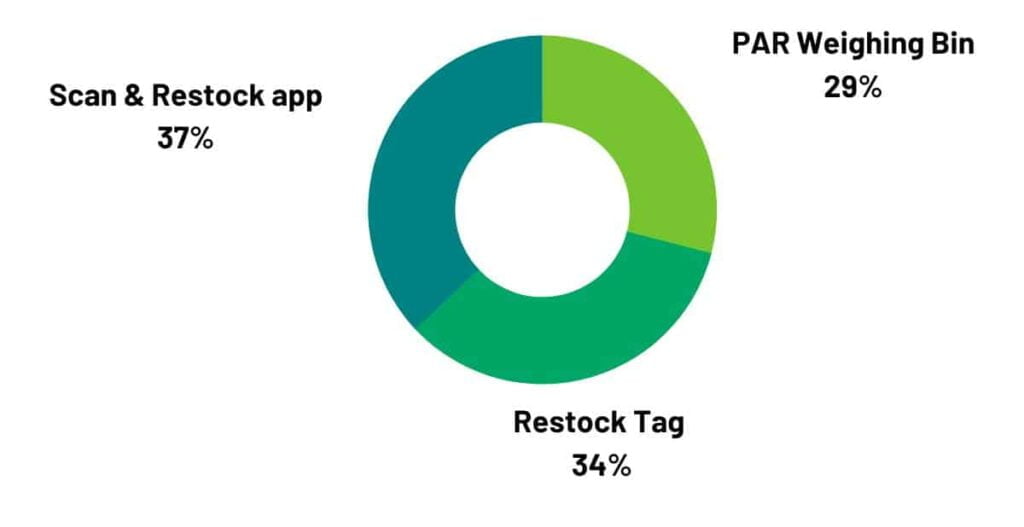

139 SKUs were selected for the pilot and were managed by one of IDENTI’s Kanban and PAR solutions. The split of SKUs by solution is noted below:

Results of the Pilot

1. Order Distribution Before and During the Pilot

During the 7-week pilot with the new hospital inventory, Sheba found:

- A decrease of 57% in the number of orders – a reduction from 51 orders down to 22 for the same timescale (Table 1)

- A decrease of 4 orders per week, reducing from an average of 7 orders a week down to 3, consisting of one main order and two small supplementary orders (Table 1)

- On the main order day of the week, a decrease from three orders down to one – demonstrating order consolidation and increased efficiency in accurately identifying supply needs (Table 1,2)

- An increase in SKUs ordered – 297 individual SKUs were ordered during the pilot, as opposed to 277 in the same period before the pilot. This could indicate that past orders did not fully reflect demand, resulting in shortages and supplementary orders (Table 2)

- A regular pattern was established – orders during the pilot were quite consistent in terms of their size, whereas past orders were more sporadic (Table 2).

2. Satisfaction Survey Results

Following the introduction of the new Kanban and PAR system:

- The level of nurse satisfaction increased from an average of 53% before the pilot to 90% afterwards (Table 3)

- All logistics tasks previously undertaken by nurses were no longer required due to the introduction of the new autonomous system. In addition, logistics workflows were streamlined. (Table 3)

A satisfaction survey was conducted among ward staff, including the Chief Nurse, the Deputy Chief Nurse, and the rest of the registered nursing team.

The survey asked the following questions:

- How satisfied are you with the general service you received?

- To what extent are you satisfied with the convenience and ease of ordering with the system?

- How satisfied are you with the way changes and updates to orders were dealt with?

- How satisfied are you with the level of missing items?

- How satisfied are you with delivery timescales?

- How satisfied are you with the new layout of stock in the storerooms?

- What is your level of satisfaction in terms of your preoccupation with orders and logistics?

3. Time spent on improvement:

During the trial, nurses no longer had any responsibilities relating to ordering stock:

- Nursing staff time spent on stock orders dropped from 2 hours 39 minutes to zero

- There was a reduction of 86% in nursing time spent on supplies organization

- Time spent by logistics staff decreased from 2 hours 41 minutes to 1 hour 13 minutes.

Conclusion

1. Having a fully automated Kanban and PAR solution resulted in the elimination of logistic tasks for nurses and significantly improved their job satisfaction.

- Nurse satisfaction increased from 53% to 90%

- A nurse survey taken after the introduction of the IDENTI Kanban and PAR inventory management system found improved satisfaction across a range of metrics.

- The highest spike in satisfaction related to flexible configuration, which resulted in better-organized stock rooms. Other positive feedback related to increased satisfaction with the materials management service and better delivery times.

- The ease of accessing supplies, the improved turnaround of stock, and the release of nursing staff from involvement in material management matters had a significant impact on levels of satisfaction among nursing staff.

2. The time logistics staff spent in the department was reduced by more than 50% during the pilot

- The new hybrid Kanban and PAR solution added accuracy and visibility into supply management, leading to a more balanced inventory. Supplies were more readily accessible to nurses, with locating stock becoming an easier task, and without surplus stock cluttering up storage spaces. Precise ordering also reduced stock-outs, ensuring items were at hand when needed.

3. Having a hybrid, flexible solution enabled the reconfiguration and reorganization of the supplies room.

- Better layout, increased storage capacity, and optimized shelf space – creating order in previously disorganized spaces.

- Less time is required to restock the better-organized supply rooms.

- It was quicker and easier for nurses to find and access supplies.

- There was more flexibility in terms of bin placement – in particular for the weight-based PAR bin, as it is an individual, portable unit that comes in 3 sizes, as opposed to being part of a fixed wall unit.

4. This pilot focused on operational improvements and did not measure financial metrics.

However, it can be seen that there is a large reduction in the time needed to manage inventory since the introduction of IDENTI’s automated Kanban bin system, and this will, of course, result in cost and resource savings. Cost savings would also be expected in relation to restocking, as unnecessary orders would no longer be placed.

5. The hospital realized the value of data-driven decision-making, taking the guesswork out of ordering. They are now using accurate usage data to achieve more precise ordering.

The data provided by the management system is being used to support planning and delivery:

- Fewer, more consistent, more accurate orders, as opposed to the erratic orders of the past

- SKU-specific restock orders, slashing the time taken by logistics staff to process reorders

- Data metrics and insights that provide materials managers with historical and real-time data, giving a clear picture of inventory, and supporting inventory management decision-making

6. The hospital is currently reviewing the further roll-out of the IDENTI Kanban and PAR solutions in other departments based on the successful results of the pilot.

Contact us to discover a more efficient and profitable way to manage your bulk medical supplies in the department.