What’s inside:

How can providers ensure the patient’s electronic health record is up to date after surgery?

New technology is simplifying this once complex task for perioperative nurses.

At the risk of being contentious, I’m going to state an uncomfortable truth – recording product usage during surgery is often inefficient. All too often nurses fail to document every reportable item into the electronic health record EHR before the patient is wheeled out through the doors.

More and more healthcare providers are resorting to using a clinical documentation nurse or are carrying out regular internal documentation audits.

It’s a shame for providers to acknowledge the limitations of their existing surgical supply documentation systems, but to continue using it anyway.

Their approach is to address data gaps by reconciling surgical records.

But that’s flawed thinking.

Why waste valuable time and resources compensating for a point of use system that doesn’t achieve its goal?

Replace the system already!

The challenges of surgical supply documentation

The truth is that traditional technology often fails to achieve data integrity in OR and procedural rooms.

- Manual Data Entry on clunky systems is time-consuming and error prone.

- Barcode Scanning can suffer from readability issues, missing data and non-recognized items.

- Other outdated automation tools commonly rely on keyed-in data when automation fails.

So, what’s going wrong?

Today’s OR and procedural labs use a wide range of medical inventory, and this can be a challenge for OR and procedural room surgical documentation systems.

This is because:

- Stock items don’t always sail through the automation. Many items contain updated codes (eg. GTIN) on the label or packet, and this revised data may no longer match the details stored in the Item Master.

- Consignment inventory may be stored off-site or on-site. Either way it is not associated with the provider prior to surgery, so a lengthy process may be required to get the item listing in the EHR.

- Bill-Only Items are delivered straight to the operating room or procedural room. These items, such as trunk stock, may not be listed in the system at all and recording them is often long-winded.

We can see that the various types of inventory can affect the efficiency of data collection in the surgical setting.

But why is this?

Surely point of use automation needs to be able to deal with ALL types of inventory???

The problem is that existing tools all focus on data-capture ONLY.

Most systems trip up at the product identification stage, which needs to take place before any item can be entered in the system.

The hospital’s item master is used as its source of truth. Every item entered into the system is referenced against this catalog, and the item can only be documented if it finds a match. There are several reasons that relying on the local item master is problematic:

- Volume of SKUs: An item master can contain hundreds of thousands of individual SKUs, making it nearly impossible to keep up to date.

- Changes to barcodes: Manufacturers make constant changes to item coding, such as updates to the GTIN code.

- Item master maintenance is often done periodically, so hundreds, or even thousands of items will become out of date in the period between the last item master maintenance and the next one.

In a survey of perioperative nurses, we asked what the main point of use documentation frustrations were, and the top issue reported was the number of items that weren’t recognized by the system.

When data entry fails, a long, manual workaround will take place before the item can be recognized and recorded. This is time-consuming and could involve staff from IT or Materials Management, in addition, the delay in documentation raises the risk of it not being recorded at all.

So, what’s the solution?

At IDENTI, we took the time to understand the specific problems of the surgical setting, and created a brand-new custom approach to surgical supply documentation that meets these challenges head on.

Here’s 5 things to love about Snap&Go, our next-generation product usage documentation tool:

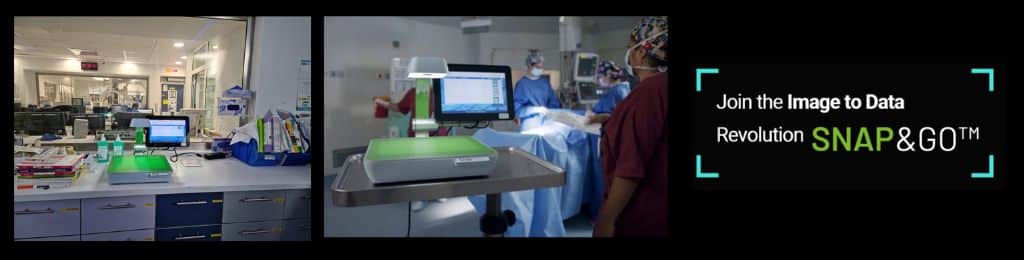

- It uses a computer vision sensor to ‘snap’ an image of each label or package. It takes just 3 seconds per item and then, that’s it, the nurse’s job is done. See perioperative nurse feedback after seeing Snap&Go in action.

- It uses AI and machine learning algorithms to convert the captured image into digital data.

- Full item details are captured – UDI, batch number, lot, expiry date – no need to fix fields or add missing data.

- Item identification is automated by tapping into a global SKU database, and is supported by a human back-office, ensuring EVERY item snapped is identified.

- Seamless integration with the ERP, EHR and MMIS ensures this vital data is promptly fed into internal workflows, boosting operational efficiency in areas such as inventory management and medical billing.

The right technology works – achieving 100% item and charge capture.

No need for additional staff or internal audits.

Snap&Go is the next-generation of surgical supply documentation.

Join the image-to-data revolution.

See a quick video on the ease of documentation using image-recognition technology.

If your healthcare provider has additional admin staff or relies on regular internal documentation audits in order to ensure a complete and correct EHR, why not keep things simple?

Contact us to discuss how technology can support you in lightening the workload and boosting OR surgical supply data capture.