What’s inside:

Technology has the power to transform relationships and aid collaboration.

That was certainly the case in this Mexican case study, where a combination of AI and RFID cabinet technology brought a three-way partnership closer together in a Fourth-Party Logistics (4PL) model.

This case study covers:

- The introduction of supply chain technology forged stronger relationships between a logistics company, a distributor, and the hospitals it serves.

- The challenges they faced managing the hydrocephalus shunts, to ensure continuity of surgical supplies.

- How RFID smart cabinet technology helped them to overcome many difficulties and strengthen their partnership.

Background

DHL’s Life Sciences & Healthcare division offers end-to-end supply chain solutions to improve the efficiency and costs involved in managing high value implants. Their customer, Medtronic Mexico, wanted to find a logistics and management solution for their hydrocephalus implants, which are used in expensive brain surgery procedures for children.

Hydrocephalus shunt surgeries can be first time implantations, or shunt replacements, that are fitted into an existing system. 4,657 Hydrocephalus Shunting Procedures were performed in Mexico in 2022. Ensuring the continuous supply of hydrocephalus implants was crucial for Medtronic and the hospitals it services, in order to ensure prompt treatment, and prevent the suffering of children.

Hydrocephalus shunts

Some information about the specialist hydrocehalus shuts used in brain surgeries.

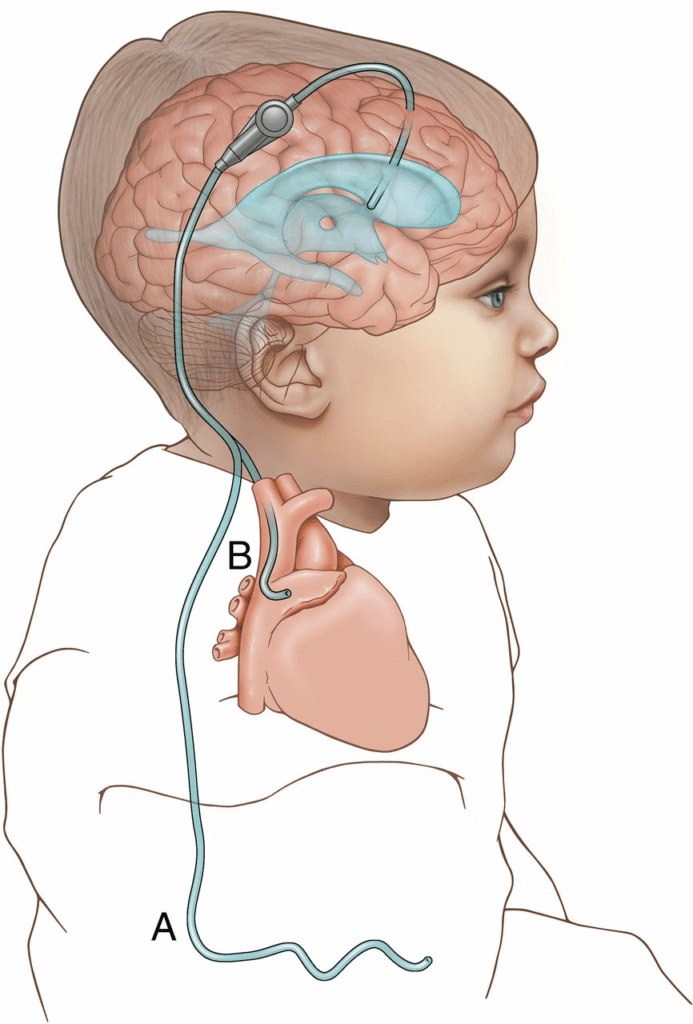

Hydrocephalus is a condition where excess cerebrospinal fluid (CSF) builds up in the brain, causing increased pressure. Hydrocephalus shunts are implanted during brain surgery to divert the excess CSF away from the brain, relieving the pressure and preventing further complications.

During the procedure a shunt is placed in the brain to divert excess CSF away from the brain to another part of the body where it can be reabsorbed and excreted, relieving pressure on the brain.

A typical hydrocephalus shunting system consists of several components, including a catheter placed in the ventricles to collect CSF, a valve mechanism to regulate CSF flow, and a second catheter that directs CSF to another part of the body, such as the abdominal cavity or the heart.

Fourth Party Logistics Model

The 4PL model, short for Fourth Party Logistics, refers to a supply chain management system where a fourth-party logistics provider manages resources, technology, and capabilities to design, build, and run comprehensive supply chain solutions on behalf of a client.

Unlike traditional logistics providers, a 4PL provider acts as an integrator, coordinating multiple logistics services and providers to optimize efficiency, reduce costs, and improve overall supply chain performance for their clients. They typically oversee end-to-end supply chain operations, including transportation, warehousing, inventory management, procurement, and distribution, often leveraging advanced technologies and data analytics to drive continuous improvement and strategic decision-making.

In the healthcare industry, the 4PL model, also known as Medical Stock Replenishment as a Service (SRS), is a specialized approach tailored specifically to healthcare needs. SRS involves outsourcing the management and replenishment of medical stock to a third-party provider. This provider is tasked with monitoring inventory levels, forecasting demand, and ensuring timely replenishment of medical supplies to prevent stockouts or overstocking.

SRS often includes advanced features such as demand forecasting algorithms, real-time monitoring, and customized reporting, all aimed at optimizing inventory levels and streamlining supply chain operations in healthcare facilities. DHL was able to provide and reinforce these capabilities through IDENTI’s RFID technology, which provides real-time implant tracking of remote inventory while activating advanced AI capabilities.

SRS, facilitated by DHL and powered by IDENTI technology, enables hospitals to delegate inventory management to DHL. With this system, DHL gains real-time visibility into every storage facility, down to each cabinet, in every hospital room.

Upon receiving alerts for replenishment, DHL promptly restocks the necessary inventory. This includes all medical supplies, implants, devices, and point-of-use charge capture data, meticulously tracked in real-time by DHL.

About DHL’s Life Sciences & Healthcare division

The division is specialized sector within the DHL group that focuses on providing logistics solutions tailored to the unique needs of the pharmaceutical, biotech, and medical device industries. The division leverages DHL’s extensive network and expertise in logistics to ensure the safe, secure, and efficient delivery of healthcare products and supplies, including pharmaceuticals, vaccines, medical devices, and diagnostic equipment.

Challenges

Medtronic Mexico had the following challenges:

- They relied heavily on DHL as their international logistics provider and wanted feel more confident in DHL’s ability to respond to providers’ demand for Hydrocephalus shunts.

- They wanted to maintain continuous stock availability, so that no child had to wait for surgery due to inventory shortages.

- Items were manually managed, which was inefficient and resulted in expiry management issues with items expiring on the shelves and contributing to high wastage costs.

- Crude inventory lists did not provide the insight needed for more informed management. Medtronic was not on-site and relied upon hospital data.

- The previous storage system lacked tight securely, resulting in implant theft that contributed to high levels of inventory loss.

- Slow documentation and elongated workflows lead to elongated “usage to invoice” timescales and consequently, long payment cycle times.

- Operating room data lacked integrity and data disagreements caused disputes between parties and took time to resolve.

DHL wanted to find an automated inventory management solution that allowed them to grow their own business, while at the same time solving their customer’s recurring problems.

“By leveraging automation and fostering trust among partners, we’ve achieved unprecedented levels of efficiency and transparency. This joint effort has not only optimized our inventory management but also paved the way for expansion and growth.”

Goals

With such a lot at stake, it was crucial to present a solution that worked for all parties.

DHL’s objectives were:

- To introduce automated storage cabinets that deliver real-time, end-to-end visibility of consignment inventory and achieve precision management of local stock.

- To provide Medtronic with real-time inventory data, giving them greater visibility and control of their inventory.

- To use enhanced inventory vision and data analytics to inform inventory management decision-making, optimize the supply of inventory to Medronic Mexico’s medical representatives, and the hospitals they service.

- To provide added value to Medtronic Mexico and fully meet their inventory management needs.

- To extend DHL’s services from third-party logistics provider (3PL) to fourth-party logistics provider (4PL), in order to offer full supply chain management.

Solution

DHL reviewed the market and selected IDENTI’s Smart Cabinet system.

This UHF RFID cabinet, powered by AI cloud management software, was felt to be the most efficient and cost-effective solution.

TotalSense provides precise implant tracking, real-time visibility, automated stock replenishment, and data to support smarter inventory management capabilities.

DHL were keen to implement a labor-lite system that provided a fully digital solution and reduced the errors and inefficiencies they were experiencing.

A vital factor in the selection of TotalSense was the shared stock visibility achieved for all supply chain stakeholders – this meant that all parties were using the same central data and were able to work with greater trust and collaboration.

Process

The project’s implementation stages included:

- Agreeing a partnership team for implementation planning with Medtronic.

- Project planning with all partners covering project definition and user requirements.

- Review and assessment of current processes and technologies.

- Visit to hospital sites where the smart cabinets were to be located, and discussion on facility preparation and roll-out with local staff.

- System development and configuration, data mapping and testing.

- Preparation of the integration of software, including directory integration and user set up.

- System testing, validation of data mapping and final configuration.

- Hardware and software installations at facility sites, followed by functional and performance testing

- User training, device tagging, and launch.

Partnership Approach

IDENTI’s work in Mexico needed to meet the needs of 3 levels of supply chain stakeholders:

- The logistics company (DHL)

- The distributor (Medtronic Mexico)

- The hospitals working with Medtronic

The solution needed to address the diverse requirements of each of these partners.

The ability to collect and share data between all parties was crucial to the success of the project. IDENTI was able to put local hardware in place and use cloud software to process and share the data, so that everyone had full real-time visibility of the inventory stored in the on-site cabinets, and also benefited from data analytics.

Results and Outcomes

IDENTI’s TotalSense cabinet is now installed in 9 Mexican hospitals and is used for managing consignment inventory for Medtronic Mexico.

The RFID smart cabinet solution has achieved the following benefits:

The collaboration between all parties involved in the supply chain management process led to significant improvements across various key areas. Firstly, there was enhanced stock visibility, with comprehensive item listings for both stock and usage, allowing for better inventory management. Additionally, the implementation of automated item-level management drastically reduced the number of expired items in stock to zero, ensuring better quality control.

Real-time tracking at the item level provided detailed insights into usage patterns, including who removed the item, for which patient, and for which surgery. This facilitated easy identification of recalled or expired products, enhancing patient safety. Moreover, automated replenishment features helped prevent shortages and stockouts by flagging up when individual items required replenishment. This proactive approach improved operational efficiency and ensured seamless supply chain operations.

Security measures were also tightened, with restricted access and user tracking helping to address implant theft. This resulted in a significant reduction in inventory losses by 21%. The implementation of a joint vision fostered increased trust and transparency among supply chain partners, leading to a shared understanding of the supply chain status and a reduction in disputes to zero.

Streamlined processes and joint agreements on data improved billing efficiency, reducing “usage to invoice” timescales by 32%. Furthermore, the system generated real-time metrics, inventory reports, and data insights, empowering stakeholders with valuable information for informed decision-making. As a result of these enhancements, DHL was able to expand its supply chain management services into a 4PL service, supporting continued growth and scalability.

Find out more about gaining full control of your specialist implants and fostering closer partnership relationships using UHF RFID cabinet technology.