What’s inside:

Ambulatory surgery center software can improve the management of medical supplies and high value stock – which can deliver real benefits for staff workloads, patient care and financial management.

We’d like to guide ambulatory care centers on how to:

- Understand why ASCs need to leverage technology for improved performance.

- See the benefits of automated inventory management in ambulatory surgery centers.

- Add accuracy to your management and operations and improve ASC inventory management data.

- Highlight the quick wins and simple solutions that make all the difference.

Ambulatory surgery centers prepare for growth

As the ambulatory care sector expands and ambulatory centers experience growth, it’s more important than ever to make sure the basic clinical, operational and financial procedures run smoothly. High up the list of vital drivers is collecting and analyzing business data that can influence growth.

Many ASCs are managing their supply chain management manually or are using outdated technology. Recent expansion and increased competition have led many ambulatory care providers to prioritize the automation of their medical inventory, in a bid to add costs-savings and efficiency into their operations.

Technology is the go-to route to modernize, and this blog aims to simplify the process and steer you through the maze of medical inventory automation.

What is it that you need? What technology is best?

We’ve kept it simple and hope that it helps.

Ambulatory centers plan for medical inventory automation

Right, so you recognize that automation is the way to go but the variety of options is just plain confusing. What next?

Selecting the right tools and technology needs careful thought.

Here are 12 initial questions you should ask:

- What types of inventory do you find most difficult to track?

- Where do you have the greatest wastage?

- Where are your data leakage points?

- Which manual processes are most time-consuming and error-prone?

- Do you need seamless interoperability with your existing healthcare information systems (HIS)?

- Are you looking for real time inventory tracking and visibility?

- Are you looking to reduce staff time spent managing healthcare inventory (nurses and logistics staff)?

- Is ease of use important to you?

- How accurate is your point of use data capture to close the inventory loop?

- Do you suffer from shortages, stockouts and surplus stock?

- What’s preventing accurate procurement?

- If you are planning further growth, is scalability important to you?

Going through this self-awareness process will add clarity to your most urgent automation needs, so, let’s try to summarize your main needs.

You will likely be looking to:

- Ensure medical inventory and supplies are available in the right quantity, at the right place, and at the right time, to support high quality, timely medical care.

- Improve clinical team efficiency by reducing nurse time spent on managing supplies rather than caring for patients.

- Produce meaningful medical inventory data that drives through accurate, timely decision-making.

- Boost patient safety and compliance with accurate patient records and improved safeguards against risk.

The top three inventory management priorities for ambulatory healthcare providers

From our experience of working with medical centers across the world, there are three main priorities that providers have:

- Achieving accurate, real-time inventory vision.

- Tracking inventory from enrollment, through storage, and including consumption.

- Using data to reduce costs and add efficiencies.

Improving medical inventory management is intrinsically linked to having the full picture of your stock, understanding demand and basing procurement of accurate forecasts.

Put simply, it’s all about data.

The three areas outpatient ambulatory surgery centers need to focus on when automating healthcare supply chain management

Looking at the three main priorities that most providers have when using a manual or outdated supply chain system, steers us towards the key solutions that would most improve their management of medical inventory:

Solution 1: Automation for the MANAGEMENT OF MEDICAL SUPPLIES

Current Challenge: Just think about the time, effort and energy it takes to manage a manual Kanban or PAR system. All that running around just doesn’t give you the accurate figures you need for efficient management. ASCs need to reduce the effort it takes to track supplies and achieve accurate and timely restock

Type of technology available: If you have an existing manual Kanban and/or PAR system in place you don’t need to start from scratch, you can add automation to your existing bins and slot in new digital bins. There’s no need to redesign your supply rooms or buy loads of new bins. Automating your Kanban and PAR system is far easier than you think and the technology available is advancing all the time. For instance, did you know that you could now get a wireless, weight-based, digital PAR bin? PAR bins have finally broken free from cumbersome units!

Benefit: Low labor- supplies management, data-driven procurement, improved forecasting.

Solution 2: Implant tracking software for the monitoring and MANAGEMENT OF HIGH VALUE INVENTORY

Current Challenge: If you don’t have a clear picture of your high value items then the financial stakes are high: hours of wasted time spent hunting down missing items, ineffective expiry management and high wastage costs, high risk items lurking on the shelves, such as recalled or expired items.

Type of technology available: There are lots of RFID cabinets so how do you differentiate between them? The most advanced UHF RFID smart cabinet systems have multiple sensors, so that nurses don’t have to stack each item the right way around. They may also use virtual cabinet technology to take care of items stored outside of cabinets.

Benefit: Reduced nurse supply chain workload, user and item tracking on high value stock, accurate restocking.

Solution 3: Achieving accurate POINT OF USE CHARTING

Current Challenge: Inadequate tools, reliance on the hospital Item Master, distraction of nurses on products, taking them away from patients, inaccurate EHR, inaccurate or incomplete inventory management and billing data. ASCs need to ensure the capture of every reportable, billable item used in surgery.

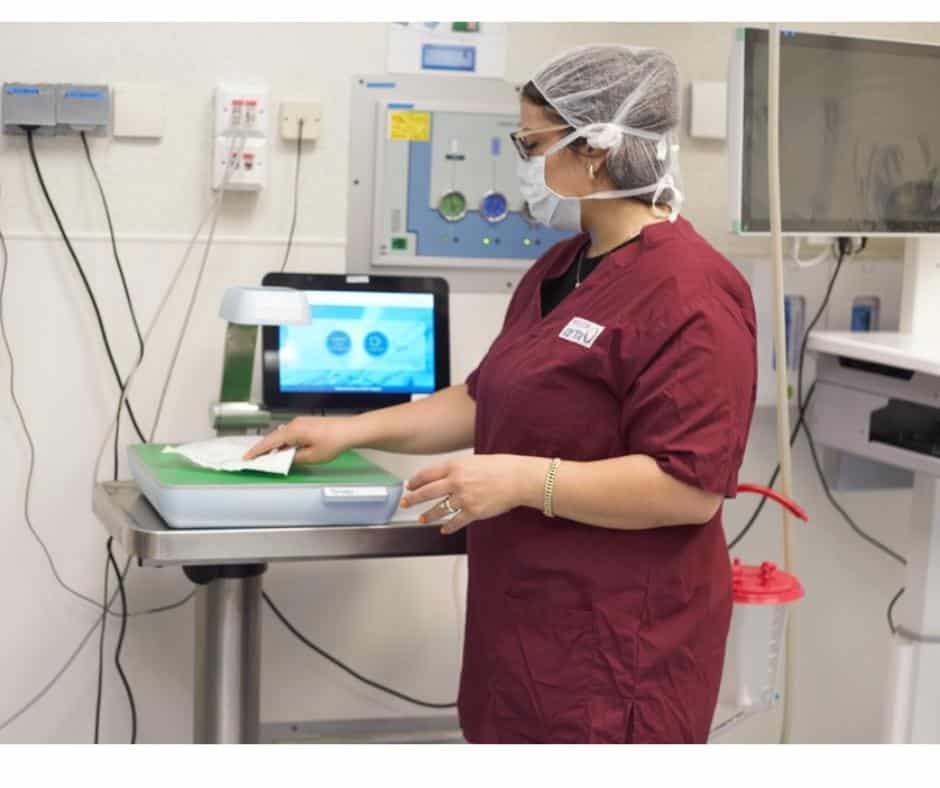

Types of technology available: Many ASCs are using manual data entry or inadequate barcode systems and the point of care is a known data leakage point. Point of use data capture systems just took a leap into the future with image recognition technology. It now takes seconds to capture each item and the tasks of product identification and surgical supply documentation in the EHR are automated! No reliance on the Item Master and no longer a drain on nurse time.

Benefit: Closing the inventory loop is vital for efficient inventory management, accurate, timely billing and patient safety.

Effective supply chain management for ASCs should cover all of these areas – achieving end to end tracking and full visibility.

In addition, each system should be easy to implement and reduce labor.

Finally, but still crucial, captured data should be interoperable with hospital systems so that it can be analyzed and shared data with hospital systems.

If work for an ASC that is struggling with poor inventory vision and is looking to use automation to improve efficiency and lower costings, we’d love to help you move forward on your journey.

Contact us for expert advice, unique products and all the support that an effective partnership can deliver.