What’s inside:

Point of care supply documentation technology has transitioned from the use of a manual system to an automated W

Supply utilization is an important element of surgical records, see this info graphic which looks at:

- The pitfalls of manual systems, stickers and implant logs.

- The downside of keying in data to the electronic health record (EHR)

- Where barcodes and other scanning systems fail.

- Why image recognition and AI are the ultimate solution for timely and accurate surgical supply documentation.

US hospitals are failing to achieve full item and charge capture in surgery

What is the impact of an inadequate point of use system? Poor surgical supply documentation costs US hospitals $7.7 billion annually and has a negative impact on healthcare management.

OR consumption data is key patient information that vital to:

- Drive internal workflows – such as RCM, billing and inventory management

- Ensure medical records are correct and safeguard patients

- Help providers to meet regulatory compliance

- Steer management to make smarter clinical, operational and financial decisions

The point of use systems used to document implant usage in surgery have evolved over the years.

Once stickers and a few notes in the ‘big book’ were the way to go, but since then EHR systems, RFID, barcodes and QR codes have become popular ways to electronically document supply utilization.

The problem is that these systems have limitations when it comes to routinely documenting every consumed item in surgery.

Issues include:

- barcode readability

- lack of barcode to scan

- partial information collected

- errors in manual entries

- system exceptions due to lack of a match in the item master

All of these problems cause delays during surgery, place a burden on perioperative nurses, and result in compensatory action in the form of post-surgery data entry, documentation reviews, and record reconciliation, just to get the patient file to reflect reality.

The systems in use simply don’t get the job done – there are way too many tech failures leading to manual workarounds and OR data quality issues.

The impact of ineffective point of use systems for supply documentation

Problems documenting product usage in surgery have many repercussions:

- Nurses are often frustrated by the time and effort required for perioperative documentation, which detracts from patient care.

- Operational workflows require consumption data to support tasks such as revenue cycle management (RCM), timely billing, procurement.

- Management requires timely and correct supply chain data to support cost-saving activities, value analysis initiatives, standardization, as well as healthcare planning, management and forecasting.

Point of use solutions for documenting product utilization in the operating room (OR)

We compared the different point of use documentation tools against different criteria to find out which technology is most effective.

We compared manual/sticker implant logs, EHR electronic health records, scanning software such as RFID, barcodes, QR codes, and the newest technology on the market, image recognition and AI.

Take a look at our assessment of the pros and cons of each system when benchmarked against key criteria that are important for healthcare providers.

DOWNLOAD LINK: You can download the infographic on the evolution of Point of Care Supply Documentation Technology.

This grid is contained in our White Paper on the issue.

What’s in the White Paper on point-of-use systems?

Let’s take a peek:

The white paper covers the following:

- Background stats to show the scale of the problem in US hospitals.

- The challenge of documenting supply utilization in surgery

- The cost of getting surgical supply documentation wrong

- Comparing traditional systems with advanced technology

- Comparison grid assessing different surgical supply documentation tools

- The features a point of use (POU) product usage documentation tool needs

- Feedback from nurses on a new image recognition tool for OR and procedural spaces.

FULL DOCUMENT: See the full document, including

background and commentary in our white paper

on Supply Utilization at the Point of Care – comparing

traditional systems vs. new technology.

About the new image recognition solution for surgical supply capture

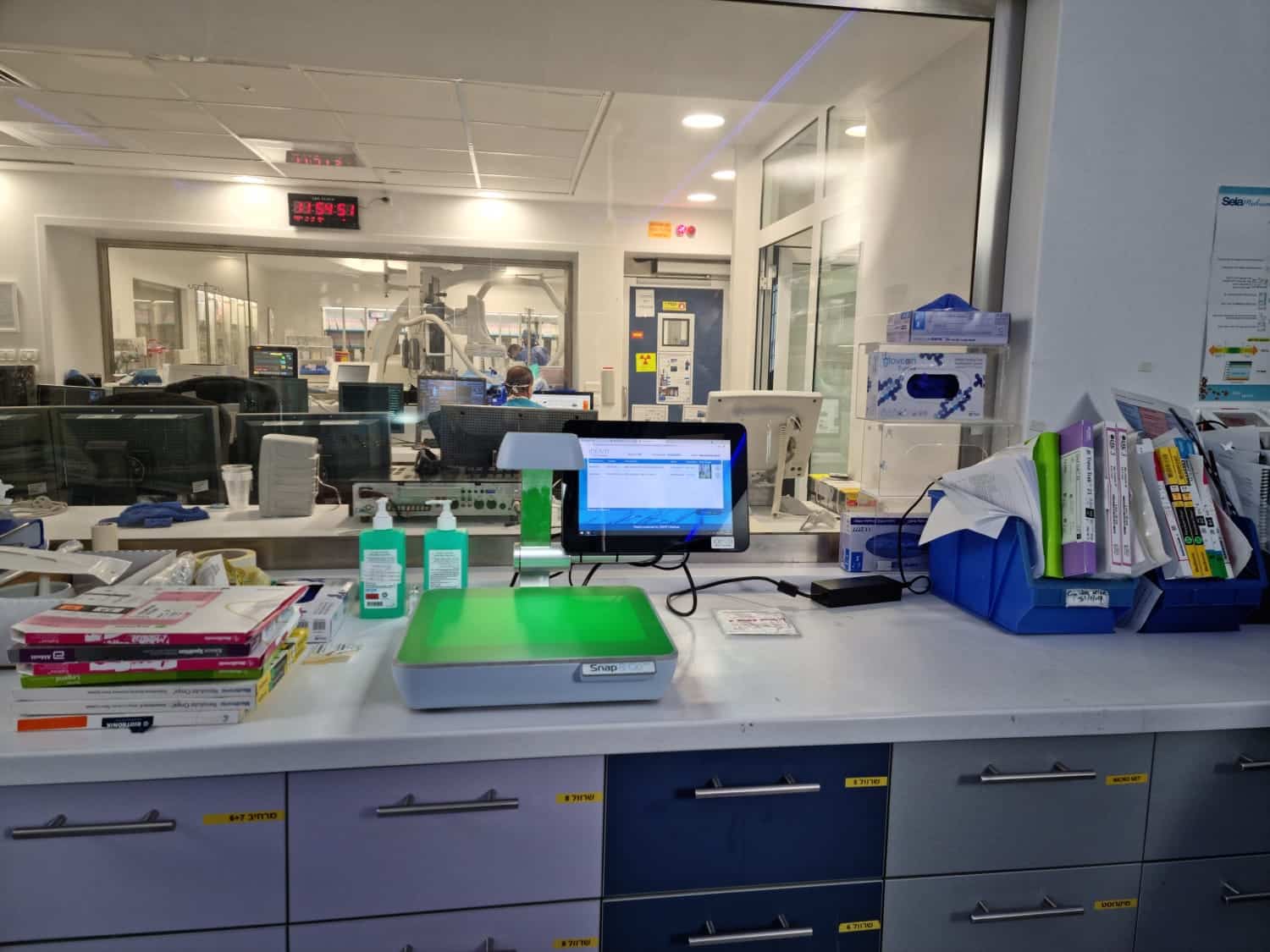

Snap&Go is a computer vision sensor that is transforming the task of supply documentation in OR and procedural settings.

Breakthrough image recognition technology ensures 3-second item capture, and managing software powered by AI and machine learning algorithms, with access to a global SKU database, ensure that product identification, validation and documentation are completely automated.

This technology is simply the future of perioperative documentation. and is nurse-approved – see perioperative nurse feedback on Snap&Go.

It’s time to join the image-to-data revolution – get in touch to step into the future.