There is common thinking to believe that missed revenue is the biggest negative impact organization can experience when surgery supplies are not properly documented. But no. Poor supply documentation compromises patient outcomes and safety. And this is the most serious thing that can happen to a health organization.

The impact of poor documentation

Optimizing the supply chain in the perioperative area and significantly improving revenue margins were always top goals for the hospital. This is why almost all point-of-use solutions available on the market are aimed at one goal – charge capture. It’s true, the operating rooms and procedural rooms are the heart of the hospital and the largest revenue generator for most hospitals. Capturing charges can affect the billing process, inventory demand planning, preventing of waste – important impacts by no doubt. But patient safety has been and will always remain the primary goal of the hospital. And this is why a solution providing barcode and analytic software will never be enough.

A study was conducted lately disclose: 82% of OR nurses said they encounter challenges documenting products during procedures, they also indicated that the biggest consequence of poor documentation is a negative impact on patient safety, especially involving sentinel events. A sentinel event focuses on identifying and eliminating serious, preventable health care setting incidents, for example: identifying expired or recalled products before it used on a patient.

Challenges detecting recalled products

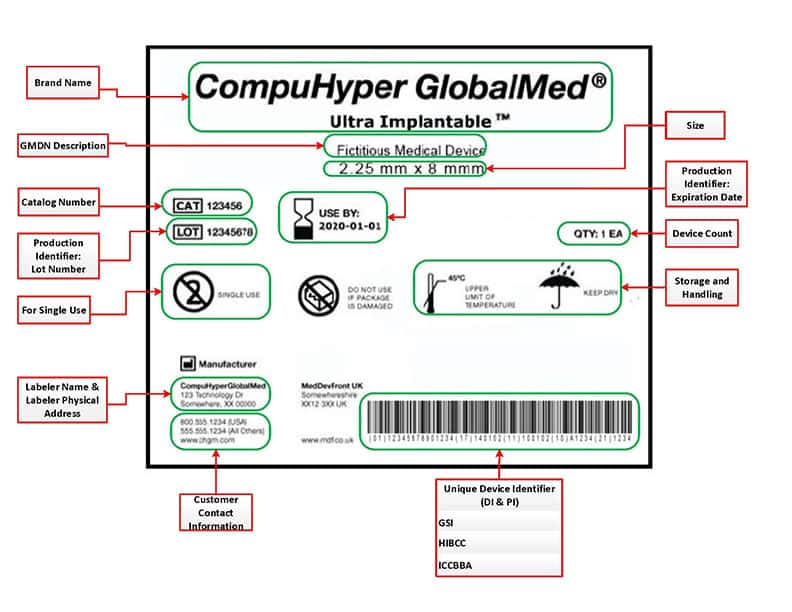

OR personnel cannot be expected to catch expiry or recall inventory if we do not give them the tools to do so quickly and efficiently. When a recall occurs only the patients treated with the affected batch will be notified (lot or batch number within which a device was manufactured). Most barcodes don’t hold batch information unless it’s a barcode with UDI format. But here comes the catch, a barco

de in UDI format changes all the time, what changes for an instant is the same value of the batch- each time a new production series requires a new batch and a new barcode. Hospitals have a hard time maintaining it and therefore give up on it. The result is a lack of tracking of batch history over time.

Our suggestion is to ditch the barcodes and move them into image recognition and object capture. Using camera and computer vision has enabled us to extract the information out of the packaging labeling simply by interpreting a single snapshot of the product. Our AI and machine learning algorithm will identify the product, validates its safety, and populate the information into the hospital’s EMR/ MMIS/ ERP software. Simple as that! Interested in hearing more ask us about Snap & Go!