What’s inside:

In this article, we’ll look at how to reduce OR supply chain costs and in doing so increase OR margins, including:

- The high cost of OR surgery delays

- How to analyze surgical case cost based on reimbursement

- Adding $1 Million to your OR profits

- OR Cost-Saving Strategies

- Working with physicians to reduce expenditure

- How consigned inventory can save OR costs

How can the operating room supply chain be made more efficient and improve revenue? Let’s take a look at some of the challenges.

The high cost of OR surgery delays

OR surgery delays are unfortunately a common occurrence, and one reason behind elongated surgery times is time wasted due to inefficient management of OR surgical inventory. Mismanagement of surgical supplies creates regular delays in OR, affecting OR utilization, and costing millions of dollars a year.

A joint study by the University of Michigan and Rutgers University found that OR delays average $1,800 per surgery, which equates to a staggering $28 million annually.

The study discovered that an average of 5–10 minutes of additional time was required for each surgery due to unnecessary delays that resulted in unplanned costs. This not only piles up the costs but also puts patients at risk who are under anesthesia for longer than necessary.

One of the main areas of surgical delays can relate to out-of-date physician preference cards (PPCs). In healthcare providers, individual physicians each have their own physician preferred items (PPIs). These lists contain the items and instruments required to carry out the surgery. The items on the list, and the related costs, can differ quite significantly per physician and in addition, each list can become out of date, with the physician requesting an alternative to a product listed during the surgery, which doesn’t appear on the PPI and isn’t on the case cart. This means that the nurse needs to leave the surgery and obtain the required item, causing delays.

It’s well known that every minute of OR time is expensive. A time study on hospital operating rooms calculated the average OR costs to be $62 per minute (not including surgeon and anesthesiologist fees).

It’s clear that if healthcare providers can improve OR surgery planning and ensure PPI is up to date, then surgeries can keep to schedule, resulting in cost-savings.

Analyzing surgical case costs to improve OR reimbursement

With the rise of fixed cost models of reimbursement, OR cost minimization is even more vital, as it directly affects OR profit margins.

Healthcare providers are looking for ways to reduce costs, reduce waste, keep the OR schedule running on time and ensure that profits are maximized.

We look at some of the says that healthcare providers are managing to reduce OR costs and boost profits by up to 15%.

Adding $1 Million to your OR profits

Because there are high levels of wastage and price disparity, there are many opportunities to make OR cost savings and boost profits. Often, it’s a combination of people, processes, tech-tools and data that add value and efficiency to OR surgical inventory management.

Managing OR surgical inventory

Inefficient inventory management is time consuming and costly. There is usually room to make cost savings, reduce the inventory, reduce waste and improve the accuracy of procurement to meet ongoing demand. Using the right automated inventory management tools can not only improve the cost OR surgical supplies, but it can also ensure that perioperative nurses have all the items required for the OR case cart – and that these items reflect the current requirements of the physician and surgery. Ensuring prompt and accurate OR surgical supply replenishment directly affects the quality of care.

Automated inventory management systems are producing clear stock visibility and data insights, which are a key driver for gaining better control of the inventory, understanding demand and informing procurement. The University of Arkansas study found that if demand and inventory were better managed, savings could range from 6 percent to 13.5 percent of total healthcare costs.

Reducing OR supply waste

The operating room can generate a lot of waste. A study by the Journal of Neurosurgery, found that around $968 in OR supplies were wasted per procedure. They estimated that 13% of the total surgical cost was due to wasted or unused supplies, including items such as sponges and sutures.

Hospitals that track and investigate levels of operating room supply wastage and put systems in place that add precision to OR surgical supply management can result in higher efficiency, lower wastage and reduced costs.

Addressing PPI variation and costs

Research suggests that giving physicians information about product pricing can result in over 17% costs savings per case.

Physicians have historically assessed their surgical inventory needs based purely on clinical issues, but involving them in supply chain discussions and value analysis committees (VACs) is a proven way to provide a wider understanding of the business implications of their selection of PPI.

These committee give a 360 review of products taking on board clinical effective, quality control, availability, pricing and more. With all parties having input, the outcome can be improved PPI standardization with physicians consulted, included and on board with the changes.

Vendor contract negotiation for OR surgical supplies

Data doesn’t just lead to informed decision making, it also improves bargaining power when it comes to OR vendor negotiations. Accurate item-level inventory and consumption data are vital elements of OR supplier contract negotiations. They give a picture of the current stock and show recent levels of demand and any emerging trends, plus they can also be used to predict future demand. These crucial figures underpin better contractual arrangements.

Today’s healthcare supply chain technology enables shared access to inventory data by supply chain stakeholders. This gives everyone confidence in the data, an excellent starting point for contract negotiations.

Understanding the profitability of reimbursement

Providers that map the actual reimbursement against the case costs will gain a clear picture of differing profit margins. This data can also be mapped against different physicians as PPI variance can really cut into margins. Just having this data is a very useful starting point for physician discussions on the cost of care compared to case reimbursement.

Although OR surgical supply costs are always going to be a high expenditure for any healthcare provider we can see that there are many ways to achieve OR cost reductions. It can also be seen that this is not just a financial matter, as improving operating room surgical supply chain efficiency will improve clinical and operational workflows, as well as boosting patient care.

OR cost saving strategies

It’s important that the issue of cost savings in the OR suite is considered strategically. There are many strands of an OR cost reduction strategy and many of them are connected. Let’s take a look at a few.

OR supply chain costs

Using automated tools to track OR inventory and document OR surgical consumption are effective ways to understand OR supply chain requirements and keep track of costs. Once you have full visibility of operating room inventory and demand you can start to improve efficiency and implement cost-savings.

Using OR product utilization data

Automated OR supply chain solutions are not only useful to better manage the operating room on a daily basis, but they can also provide valuable data analytics. These data insights give management visibility into the operating room and an understanding of the issues. Data-driven decision can lead to improved quality of care at reduced cost as well as accurate forecasting.

Creating a culture of cost awareness

Cost awareness should not just be a concern for management, there should be an organizational culture that understands the importance of financial efficiency for optimum performance.

Some hospitals are using system data to provide physicians with cost of care data so that they can keep on top of changes and look at alternative products if the costs creep up.

When there is a culture of cost-awareness, staff often come forward with suggestions for more efficient and cost-effective ways of working, including recommending new healthcare technology that they may have heard about from their professional networks or past employment.

Adoption of cost innovation

Technology saves money. Period.

It:

- Reduces operating room (OR) supply waste

- Improves staff capacity by simplifying workloads and expediting tasks

- Helps healthcare organizations to function on a reduced workforce

- It reduces inventory, staffing, and operational costs

- It boosts profits and reduces costs

The trick to using technology for maximum effect is to select the right technology that not only effectively collects data but is also interoperable and able to share information with hospital systems.

How to present costs to physicians and reduce costs

We’ve looked at the important role of physicians as part of an OR cost reduction strategy but there are two important elements to note.

Compare vendors: Physicians will benefit from seeing the full picture so when discussing pricing it’s best to compare several vendors. This will help them to understand the price points of products they prefer when compared with a similar product offered by suppliers.

Compare vendors with benchmarks: Physicians often appreciate seeing vendors benchmarked against each other, and also against industry norms. This really gives them an idea of which suppliers have the most competitive pricing.

In some organizations, these discussions take place in a multi-disciplinary value analysis committee.

OR Cost Savings Strategies

Product and pricing research: With so much competition in the market there are often opportunities to broaden the supplier base and find cheaper prices for the surgical supplies you commonly use. Research may look at criteria such as the cost of the product, the availability of alternative products that cost less, and the quality and clinical effectiveness of the alternative product. OR surgical supply cost benchmarking can be a valuable exercise.

Any switch of product should never be about price alone, the alternative needs to perform the same, if not better, to be substituted.

Using supply chain analytics: Automated supply chain technology will provide all the data and analytics needed to create a streamlined and perpetual inventory. This will be achieved by removing zero turn items, reviewing PAR levels, reducing wastage, better managing expiry and understanding demand trends.

Supply chain innovation: Providers that move with the times are able to stay ahead of the competition. Healthcare technology moves at a fast pace and systems can become outdated over time, offering less functionality or efficiency than new technology. Some providers have healthcare innovation specialists who watch the market and look at the best technological advances for their organization. Others are involved in networks, or visit conferences to stay aware of new developments in the market.

It’s important to look not just at the cost of new technology, but at the return on investment. The right technology can make a significant impact on labor, costs and OR revenue. Seeing the big picture and understanding the impact of accurate, timely data collection, documentation and analytics will help organizations to evolve.

Supply chain workflows: When we talk about technology, we need to remember the impact this can have on reducing administration and routine tasks. Today’s healthcare organization is often understaffed and if there are ways to reduce, for example, the supply chain admin burden on perioperative nurses, then this can actually offset the effect of a reduced workforce.

How consigned inventory can save OR costs

Consigned products are based at the hospital site but managed by the vendor who retains full responsibility for them until they are used. This means that any wastage due to items becoming obsolete or expired is not the hospital’s responsibility, and cash-flow can be improved by paying items on a ‘pay as you go’ basis.

The consignment method of managing OR surgical inventory can be beneficial for some providers. Many organizations have small percentage of their stock as consignment, so a mix of the two systems can be a good approach too.

How IDENTI supports hospital Operating Room optimization

IDENTI Medical is a specialist in the OR healthcare technology sector, with a range of advanced, patented solutions that deliver full data integrity for optimized OR revenue and efficient surgical supply management.

Solutions include:

TotalSense – A UHF-RFID smart cabinet delivering real-time visibility, item level tracking, expiry management, automated restocks and data analytics.

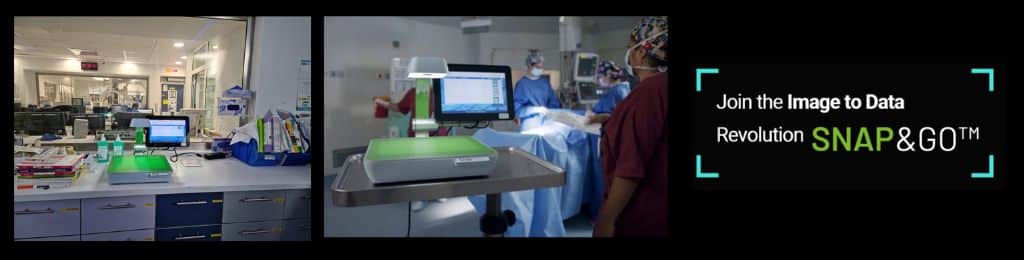

Snap&Go – Next-gen OR documentation via a computer vision sensor powered by AI technology and a virtual item master for 3 second item capture straight into the EHR.

Digital Kanban & PAR – OR management isn’t just about high value inventory, it’s also about bulk supplies. Our digital Kanban & PAR solutions add automation and precision to the management of medical supplies.

It’s clear that to be efficient, mechanisms need to be in place to monitor the inventory in real time and ensure that management have continual vision of stock levels and consumption. This key data underpins OR efficiency, patient safety, inventory management and OR revenue.

If your healthcare organization is looking for solutions that are custom-built for the OR setting, then contact us to discuss the challenges you face.