What’s inside:

There are proven tricks to reducing healthcare and medical device supply chain costs, and we’re going to share them!

Effective healthcare inventory management requires tight control of expensive medical inventory, as well as lower-value items and bulk medical supplies.

This blog will cover five common cash-burners for the hospital supply chain and how inventory management software can add speed and efficiency to maximize your medical device supply chain.

Avoid these mistakes to stop burning your budget!

Healthcare providers the world over strive for two key financial objectives: to reduce costs and improve value.

The medical device supply chain is a critical area with great potential cost-cutting and efficiency enhancement, which can have an impact on organizational performance.

So, let’s dive into the five major culprits that drain supply chain budgets in IDNs, hospitals and ambulatory surgery centers.

1. Bloated Medical Supplies Inventory:

A bloated inventory of medical devices and supplies can be a major drain on the medical device supply chain budget. This excess may consist of:

- Products that are no longer in use

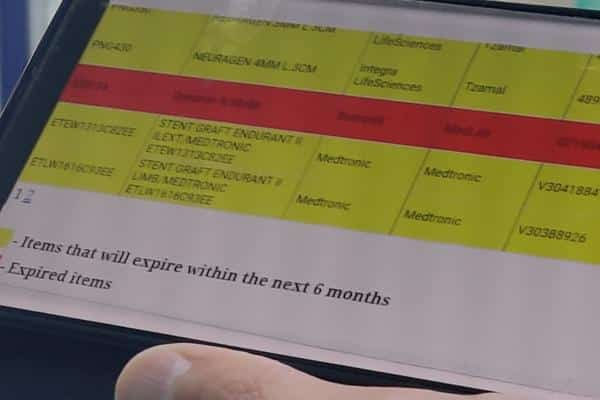

- Expired items

- Surplus stock

To tackle this issue, organizations must strive for real-time inventory visibility and automated expiry management. This will give a clear picture of stock and consumption, which will in turn inform demand forecasting. By harnessing accurate, data-driven insights, hospitals can more efficiently manage their medical device inventory as part of a smarter medical device supply chain strategy, reducing the cost of unnecessary stock.

2. High Healthcare Supply Chain Waste:

Insufficient control within the medical device supply chain can lead to a staggering 10% wastage, imposing substantial costs on healthcare facilities.

Addressing this problem may involve the implementation of:

- An automated expiry management system that monitors stock and helps to prioritize the usage of older items.

- Accountability through user and item tracking. Loss can be reduced by prompt action, for example, identifying any items that were removed but remained unused – and immediately investigating these.

Reducing wastage not only optimizes the budget but also aligns with sustainable and responsible healthcare practices.

3. Product Variance and the Goal of PPI Standardization:

Minimizing product variance plays a pivotal role in supply chain budget optimization.

Healthcare organizations can achieve this by:

- Consolidating the supplier base

- Reducing orders of similar products from multiple vendors.

- Benchmarking pricing variance to identify the best-value products

- Involving clinicians in supply chain discussions and promoting standardization through Value Analysis Committees

Having accurate and up-to-date supply chain data helps to identify supply chain inefficiencies and discuss these with clinicians too. Data-driven conversations and informed decision-making can lead to more cost-effective choices.

4. High Upfront Costs in Hospital Materials Management:

The regular process of purchasing inventory based on anticipated demand and then holding it in stock for extended periods until it is used, can place a financial burden on cash flow.

This way of working results in:

- Expensive holding costs

- Store room capacity issues

- An increased risk of waste due to expiry or loss.

To address this challenge within the medical device supply chain, exploring consignment inventory arrangements can be beneficial. With this arrangement, suppliers retain ownership and responsibility for items, until they are actually used. Stock may be stored at the supplier’s location or at the healthcare provider.

Consigned inventory minimizes upfront costs and mitigates the risk of unnecessary waste.

The right smart cabinet makes managing consigned items a transparent and collaborative process.

5. Non-Optimized Healthcare Vendor Contracts:

Many healthcare providers unknowingly enter into contracts with suppliers that do not offer the best deals. Vendor contract inefficiencies in the medical device supply chain often go unnoticed, but they can quietly inflate budgets year after year.

To optimize contracts providers can:

- Leverage inventory data to demonstrate purchasing and consumption figures.

- Negotiate volume-based discounts, rebates, and more favorable payment terms.

- Improve forecasting based on data-driven insights.

Establishing transparency and trust with supply chain partners by sharing access to the inventory management system can foster collaborative decision-making. Employing AI-driven forecasting can also aid in predicting demand accurately, further enhancing the negotiation process.

Improving hospital supply chain management

Effectively managing the medical device supply chain budget is a vital component of financial performance by healthcare organizations.

By using innovative healthcare supply chain systems that addresses these five common pitfalls, healthcare executives can optimize costs, increase efficiency, and enhance overall value.

Embracing data-driven insights, advanced technologies, and collaborative decision-making ensures a streamlined and sustainable medical device supply chain that aligns with both financial and patient care goals.

If you need to add efficiencies into your hospital supply chain management then it’s time to contact us for ideas on the role technology can play in reducing labor, lowering costs and adding efficiencies.