An RFID Smart Cabinet, when implemented in operating rooms and other medical procedural settings, is a crucial tool for managing information about medical implants and other high-value inventory. The technology tracks at individual item level tagged items stored inside the cabinet, including batch numbers and expiration dates.

The smart cabinet automatically records when items are placed in, taken out of, or returned to the cabinet. Using face or finger recognition, or an NFC card, staff members accessing items in the cabinet are also documented — all without anyone touching a computer screen.

Today, leading providers of cloud-based data management services understand the importance of having a smart cabinet in their line of products. Realizing that the inventory stored in these cabinets is of high value and that current payment terms are trending towards pay-per-use or consignment arrangements, these providers needed to include a solution in which medical supply companies could manage their inventory remotely, in real-time at point-of-use in the hospitals.

RFID Smart Cabinets Technology

The most advanced smart cabinets incorporate a new generation of ultra-high frequency (UHF) RFID tags that are capable of transmitting longer and can be covered by multiple antennas. This enables every stocked item to be read, no matter the size or placement of the items within the cabinet. Specialization in such technology requires in-depth knowledge of RFID technology, its capabilities, and applications. Therefore, few companies manage to provide the high level of accuracy required in the medical sector.

The first generation of smart cabinets relied on 13.56 Mhz HF (high frequency) RFID technology that required antennas to be installed on (or in) the shelves, which allowed for a limited reading range of up to 10 cm from the tag. It also dictated that the RFID tags be positioned precisely on each item. The second generation of RFID technology is based on an ultra-high frequency (UHF) range of 868-952Mhz which enables reading of the RFID tags no matter where they are attached to the item or where the item is placed within the cabinet.

New GS1 standard for Item Identification

The GS1 (Global Standards 1) recently adopted a new standard for item identification that permits for the use of one of two methods to obtain GS1 compliance: barcoding or UHF RFID. Several multinational medical suppliers, including Johnson & Johnson and Boston Scientific, have opted to use UHF RFID and are now in the process of tagging all their products accordingly.

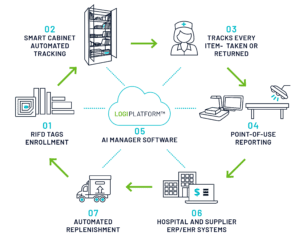

IDENTI provides a complete solution for the next generation of Smart Cabinets that includes advanced UHF RFID embedded in the cabinet and a seamless connection to cloud services and business intelligence-based management software, connecting all stakeholders in the medical supply chain.