What’s inside:

In order to optimize operating room supply chain management, healthcare organizations are looking at a range of solutions.

This article looks at:

- Integration of the supply chain into OR

- Role of the Perioperative Supply Chain Coordinator

- Perioperative supply chain shortages in times of crisis

- Cost-optimization in the OR

- Technology to boost operating room supply chain management.

An Integrated operating room supply chain

In years gone by, healthcare was managed in siloes and there was little integration between clinical and operational teams.

As healthcare management becomes ever more complex, it is clear that forging greater collaboration between hospital departments and functions is crucial for more integrated operating room supply chain management and enhanced patient care. Providers today often provide opportunities for key OR staff to get involved in operational discussions.

Inter-disciplinary teams, including OR, can now see the benefit of working together. For example, Physicians historically decided on their own preference items and were not involved in supply chain management. These days there are often ‘physician champions’ who are involved in value analysis committees (VACs), where there is discussion over the supply of surgical items.

The VAC committee members may include physicians, materials management, supply chain, finance, OR Managers, nurses, administrators, and even medical device company reps. These committees are charged with reducing inventory costs, identifying unnecessary supply chain expenditure whilst underpinning the quality of care.

Historically OR surgical inventory purchasing decisions were driven physician preference, but these days value analysis committees are commonly in place to ensure more standardized perioperative supply chain that delivers both clinical and financial gains.

With PPI making up 40-60% of healthcare supply expenditure, gaining control of this pricey expenditure can be an effective way to reduce operating room supply chain costs.

Outlining the responsibilities of a Perioperative Supply Chain Coordinator

An OR Supply Chain Co-ordinator is a role that is sometimes seen in larger organizations. This role ensures that the operating room is well-stocked with the necessary supplies and equipment, so that physicians and clinicians can deliver timely and high-quality care.

When surgical inventory is well managed and controlled this has a direct impact on surgeries taking place on time, without any delays.

An OR Supply Chain Co-ordinator may also be involved in OR supply chain budget management, new product evaluations, vendor contract compliance and OR supply chain technology.

The role sits in-between the clinical and operational functions and requires knowledge of the OR supply chain process, as well as the surgical inventory requirements of an operating room.

optimize operating room supply chain with automated efficiency

Supply chain disruptions during and after COVID 19 forced many healthcare providers to tackle deep-rooted supply chain inefficiencies, and to seek better resilience.

Gaining a full understanding of the items required and the quantities needed is central to avoiding surpluses and stock-outs.

Poor perioperative supply chain visibility and inaccurate consumption data made it extremely difficult to understand stock levels and plan procurement.

Post-pandemic, providers are realizing the value of inventory management date as part of care delivery, medical billing and inventory management.

Cost optimization in the OR

Automation is increasingly being used to give organizations clear vision of their inventory. This can help OR cost control by:

- Rotating stock to prevent OR supply wastage by expiry

- Procuring just those items required and reducing the inventory while maintaining surgical case preparedness

- Removing zero-turn items from stock and using data to prevent inventory and obsolescence

- Standardizing surgical inventory and supplies

- Streamlining OR workflows to reduce the supply chain burden on perioperative nurses, addimg extra capacity to the team

- Using OR data for enhanced vendor management

Best practices for OR inventory management

Many providers are using technology to optimize OR workflows. Healthcare supply chain automation tools are a key element of OR supply chain optimization.

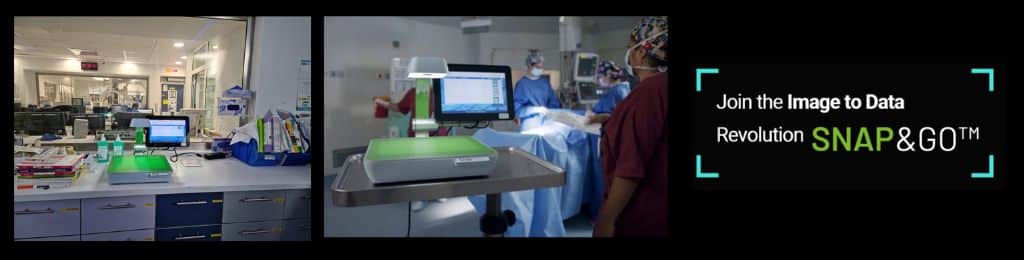

These may include an automated, smart cabinet, that stores and monitors medical devices and implants, as well as a OR point of care documentation tool, for capturing consumption.

When the right health technology is installed in the operating suite it brings immediate visibility of the inventory and utilization. This vital OR data is what drives through informed decisions, precision procurement and more efficient supply chain management.

It is a combination of increased integration of clinicians into the supply chain, along with automated healthcare technology that is optimizing operating room supply chain management.

IDENTI Medical provides specialist data sensing technology for the operating room ensuring item level tracking of stock items and swift, efficient documentation of every reportable, billable item used in surgery.

If you need more robust data to better manage your OR supply chain and improve product and PPI standardization, then contact us to look at the role of technology in optimizing OR.