What’s inside:

Discover how automated replenishment systems are transforming hospital supply management. This guide explains the Necessity–Value–Demand Framework matches the right level of automation to each product, from high-value surgical implants to everyday essentials.

Learn how to:

- Assess each item by necessity, value, and demand.

- Calculate Product Automation Scores to prioritize automation where it matters most.

- Assign the most efficient automation tools, from Digital Display Tags to Wireless PAR Weighing Bins.

- Reduce stockouts, minimize waste, and improve staff efficiency.

- Make data-driven decisions that support patient safety, financial health, and clinician satisfaction.

Whether you’re managing disposable gloves or critical implants, you’ll understand how a hybrid, strategic approach to automation maximizes efficiency and cost-effectiveness across your hospital supply chain.

Automated replenishment systems are transforming how hospitals manage supplies, balancing high-value implants with everyday essentials. Some products are high-value and used daily, while others are inexpensive but essential to keep in stock at all times. Traditional manual or “one-size-fits-all” inventory approaches are inefficient, often leading to waste, stockouts, and wasted staff time.

The pressure on supply chain teams has never been greater. Hospitals are juggling rising supply costs, ongoing staff shortages, and the need to support clinicians without pulling them away from patient care. At the same time, reimbursement models are shifting toward bundled and value-based payments, making efficient supply management a direct factor in financial performance. This is why investing in automated replenishment systems is so critical.

Automation is becoming essential, but automating everything at the same level doesn’t make sense. High-value surgical implants require constant oversight, while lower-cost supplies may only need lightweight monitoring. Without a clear framework, hospitals risk overspending on unnecessary automation or under-automating where it matters most.

With IDENTI’s AI-powered supply tracking solutions, hospitals can use the Necessity–Value–Demand Framework to match the right level of automation with each product. When paired with IDENTI’s automated replenishment systems, the framework ensures smarter supply management, lower costs, and maximum efficiency.

Let’s break down how it works.

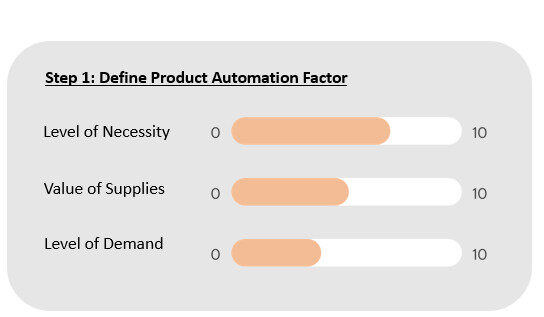

Step 1. Define the Product Automation Factor

Every item in a hospital’s supply chain can be analyzed based on three criteria:

- Level of Necessity: Is this supply critical to patient safety or routine care?

- Value of Supplies: What is the financial risk of overstocking or losing this item?

- Level of Demand: How frequently is it consumed on the floor

For example, sutures used daily in surgery would rank high in all three categories, while a rarely used wound dressing might score much lower.

By evaluating supplies this way, hospitals can determine which items need tight control and which are safe for light-touch automation, ensuring IDENTI’s automated replenishment systems target the right priorities.

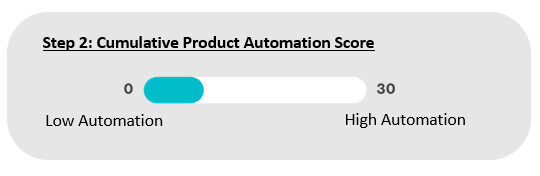

Step 2. Calculate the Cumulative Product Automation Score

The three factors are combined into a single Product Automation Score, helping hospitals avoid wasting resources on low-impact automation.

- Low scores: ideal for lightweight monitoring with low automation (e.g., disposable gloves)

- High scores: require advanced, continuous automation (e.g., cardiac stents or implants)

This scoring ensures every automation decision is both data-driven and cost-efficient, a crucial win for hospitals under financial pressure.

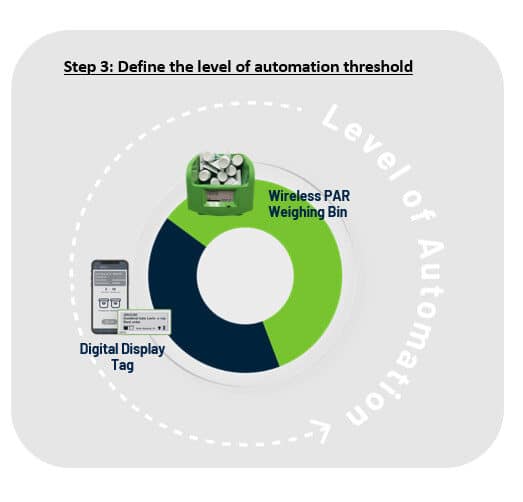

Step 3. Define the Automation Threshold

Once the automation score is set, products are mapped onto the Hybrid Automation Clock. Hospitals can then assign the most efficient automation solution, such as:

- Digital Display Tags (ESLs): For mid-range items needing real-time visibility without heavy oversight. Nurses can update stock with a click or phone tap on the NFC-enabled tag, feeding data straight into IDENTI’s automated replenishment systems.

- Wireless PAR Weighing Bins: For high-value or high-usage items that demand continuous, hands-free tracking and automatic restocking.

In practice, this hybrid model would suggest using Digital Display Tags for disposable gloves, while surgical implants are monitored with Wireless PAR Weighing Bins. Together, they create a tailored approach to hospital supply automation.

What are the Benefits of Automated Replenishment Systems in Hospitals?

Using the Necessity–Value–Demand Framework hospitals can:

- Reduce stockouts and waste by automating supply orders based on actual demand and value.

- Improve staff efficiency by eliminating manual counts and guesswork.

- Align automation costs with supply value so budgets go further.

- Gain real-time visibility into usage trends and upcoming supply needs.

Instead of applying the same automation method everywhere, the supply-specific score enables data-driven decisions that maximize the effectiveness of automated replenishment systems.

Why Automatic Replenishment Systems Matter

Hospitals operate in an environment where even small supply chain disruptions can have serious consequences. A single stockout in a high-demand department can delay procedures, impact patient care, and frustrate staff. On the other hand, overstocking low-demand supplies ties up budgets and wastes valuable storage space.

Reliable and automated tracking changes the equation:

- Patient Safety: Supplies are always on hand when needed, reducing the risk of delayed or canceled procedures.

- Financial Health: Smarter replenishment reduces waste, prevents unnecessary orders, and ensures budgets are directed toward critical items.

- Staff Satisfaction: Clinicians spend less time hunting for supplies and more time at the bedside, which boosts morale and reduces burnout.

- Data-Driven Decisions: Automated tracking generates insights into supply usage patterns, enabling leaders to forecast demand, negotiate better contracts, and plan more strategically.

Ultimately, having reliable, automated supply tracking isn’t just about logistics; it’s about giving hospitals the stability they need to deliver consistent, high-quality care in a challenging healthcare landscape.

Automated replenishment systems are only as effective as the strategy behind them. By applying IDENTI’s Necessity–Value–Demand Framework, hospitals can customize automation across their supply chain. Whether through Digital Display Tags or Wireless PAR Weighing Bins, the result is a streamlined, cost-effective workflow that keeps clinicians focused on what matters most: patient care.

Ready to see how automated replenishment systems with IDENTI’s Necessity–Value–Demand Framework can transform your hospital supply chain?