Workflows in surgical spaces all have the same objective – patient safety. Validating medical devices, tissues and implants prior to consumption is a crucial step to preventing ‘never-events’, yet the majority of hospitals and ASCs have holes in their expiry and recall management procedures.

The truth is that the systems and tools that hospitals use for Procedure Room and OR utilization are letting them down. They are simply not robust enough to prevent a few expired or recalled products from ending up in surgery, and putting patients lives at risk.

Don’t ‘settle’ when it comes to expiry and recall management

It seems that many hospitals and ASCs are ‘settling’ for their point of use itemization systems, despite the limitations. They put up with system snags and safety shortfalls because they assume that there is nothing better out there.

Recall and expiry safeguards are important, and it really is just a matter of finding the right tool to add increased protection to surgical procedures. When it comes to patient safety, there’s no room for ‘second best’, it’s time to find a tool that’s fit for purpose!

Current systems for item validation

Many hospitals and ASCs now use RFID cabinets to store their medical devices, tissues and implants. It is this stock that comes under UDI regulations and needs to be tracked.

Automated cabinets generally do a good job of tracking implants and devices (although not all! – here’s a good smart RFID cabinet)

These cabinets help healthcare organizations to track items and rotate their stock, so that soonest to expire items are used first and any items that have actually expired or have been recalled can be removed.

But the limitation here is that they can only track what they store. They can’t:

- Report on whether a product was actually used once it was removed

- Make a link between an item and a patient

- Track items that were used in surgery that did not originate in the cabinet

So, RFID cabinets alone cannot be relied upon for full expiry and recall management. The ‘last line of defense’ is at the point of care.

Point of use itemization

The point of care is a known weak point in hospital UDI tracking. It is the hardest place to get every item scanned, checked and digitally documented on hospital systems.

There are many reasons that current digital item identification and recording systems fail:

- RFID and barcode scanners that are used in surgical spaces can only work with items already in the hospital system, they can’t cope with trunk stock. Yet trunk stock is commonly used in many hospitals, particularly for complex operations. The majority of trunk stock is high value medical devices and implants – the most expensive and critical items to record.

- Barcode scanners are inefficient – they have problems recording all the data required, and in particular the expiry date is not always captured.

- Barcode and RFID scanners cannot cope with any variance between the data scanned and the Item Master List – errors trigger time-consuming workarounds that often fall down half way through, resulting in the item taking overly long to document or not being recorded at all.

With barcode and RFID readers not being an effective solution for POU item capture, what is the alternative?

A different approach to expiry and recall management

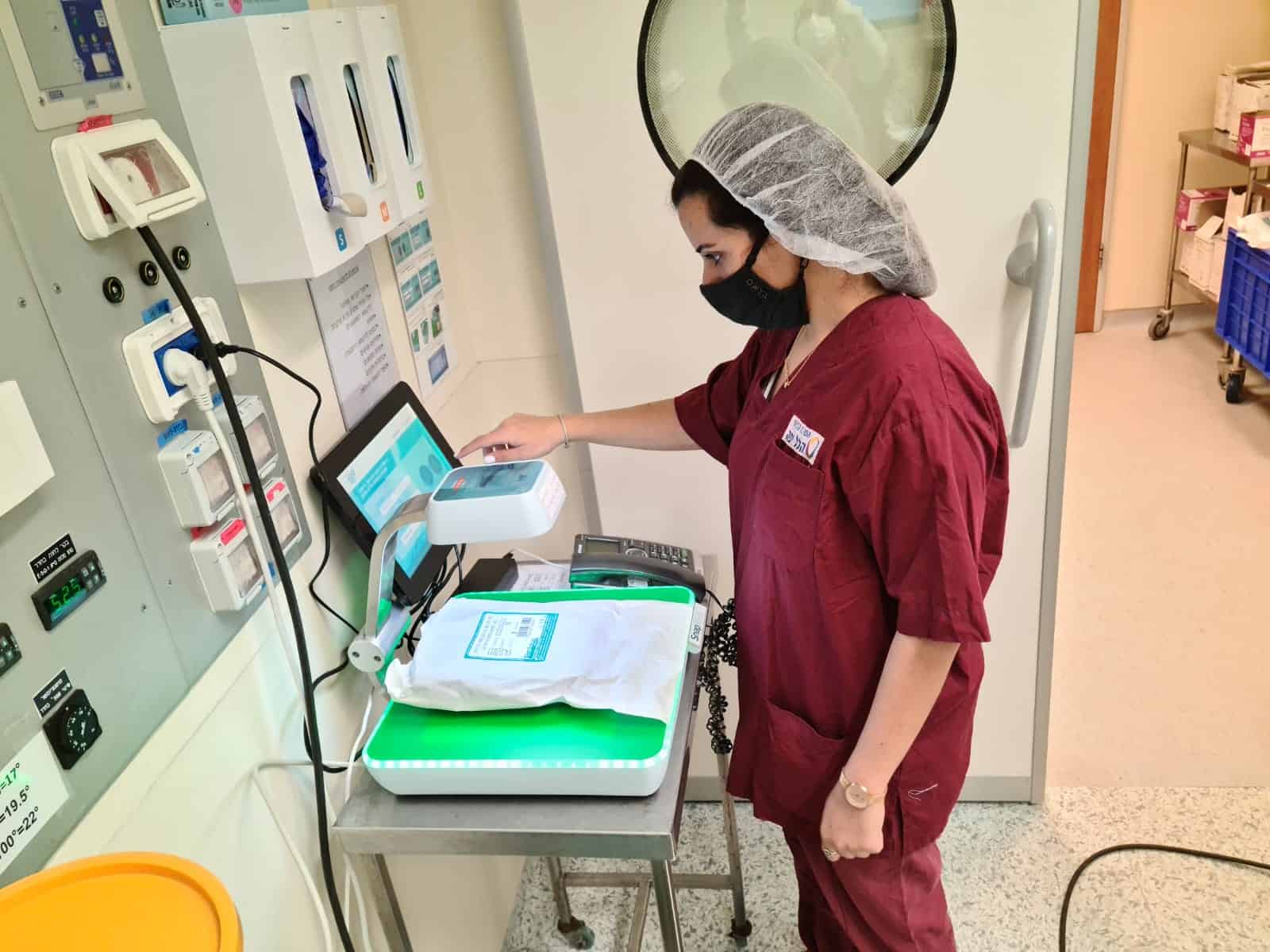

Because traditional methods have failed, IDENTI Medical decided on a completely different approach. IDENTI recognized the shortfalls of both RFID and Barcode scanning at the point of use, and decided to develop a method that would capture ALL products, whether they were on the Item Master or not. And that’s how Snap & Go was created.

Snap & Go POU expiry and recall management

Snap & Go’s image-recognition technology captures full data on each product and taps into a global SKU database.

It’s quick and simple to use – the circulatory nurse just takes a ‘snap’ of each product’s packaging to:

- Capture full UDI

- Real-time expiry and recall alerts

- Synch the data to the EHR and ERP

Snap & Go does all of this in just 3 seconds!

Our award winning tool provides real-time, pre-consumption expiry and recall alerts so that ‘never-events’ can be avoided. Snap & Go can record ANY product – hospital stock, consignment, trunk stock. It even digitalizes completed manual count sheets.

This perioperative software for data capture can be used in conjunction with an existing RFID smart cabinet or on its own.

Snap & Go is your surgical data capture solution – it’s the new cool tool that procedure rooms need.

What are the outcomes?

Snap & Go is your complete point of use data capture solution. It’s not just for expiry and recall management, it delivers so much more.

When using Snap & Go you get:

- Full POU item capture

- Full charge capture

- Optimized billing

- Optimized reimbursement

- UDI compliance

- Real-time expiry and recall alerts that prevent Never-Events

- Reduced wastage

- Accurate, data-driven procurement to prevent the surpluses that often lead to expiry issues

- Robust expiry and recall management

- Usage reports to help inform management decisions

- Inventory management reports to inform procurement

Snap & Go is a safety net for your surgical spaces and it catches all your procedure room data, giving you full protection and optimum performance.

What do hospitals think of Snap & Go?

“This system is excellent! Easy to photograph each item. It reports correctly”

“This very user-friendly system easily allows us to reach almost 100% reporting”

“This is the first time we are using a system that documents all the items we use in surgery”

Hospitals no longer need to settle for ‘good enough’.

It’s time to find the ideal partner.

Snap & Go is the robust tool you’ve been waiting for. Finally a way to strengthen your expiry and recall management, achieve full inventory visibility and gain complete control.

Call us for a demo.

See a video of Snap & Go.