What’s inside:

Hospitals lose millions each year from missed charges in orthopedic procedures due to item-master gaps, bill-only implants, and incomplete documentation. This case study examines a complex orthopedic elbow surgery and how charge capture with computer vision revealed major discrepancies in the current implant and consumable documentation.

Background: Challenges in Orthopedic Surgery Charge Capture

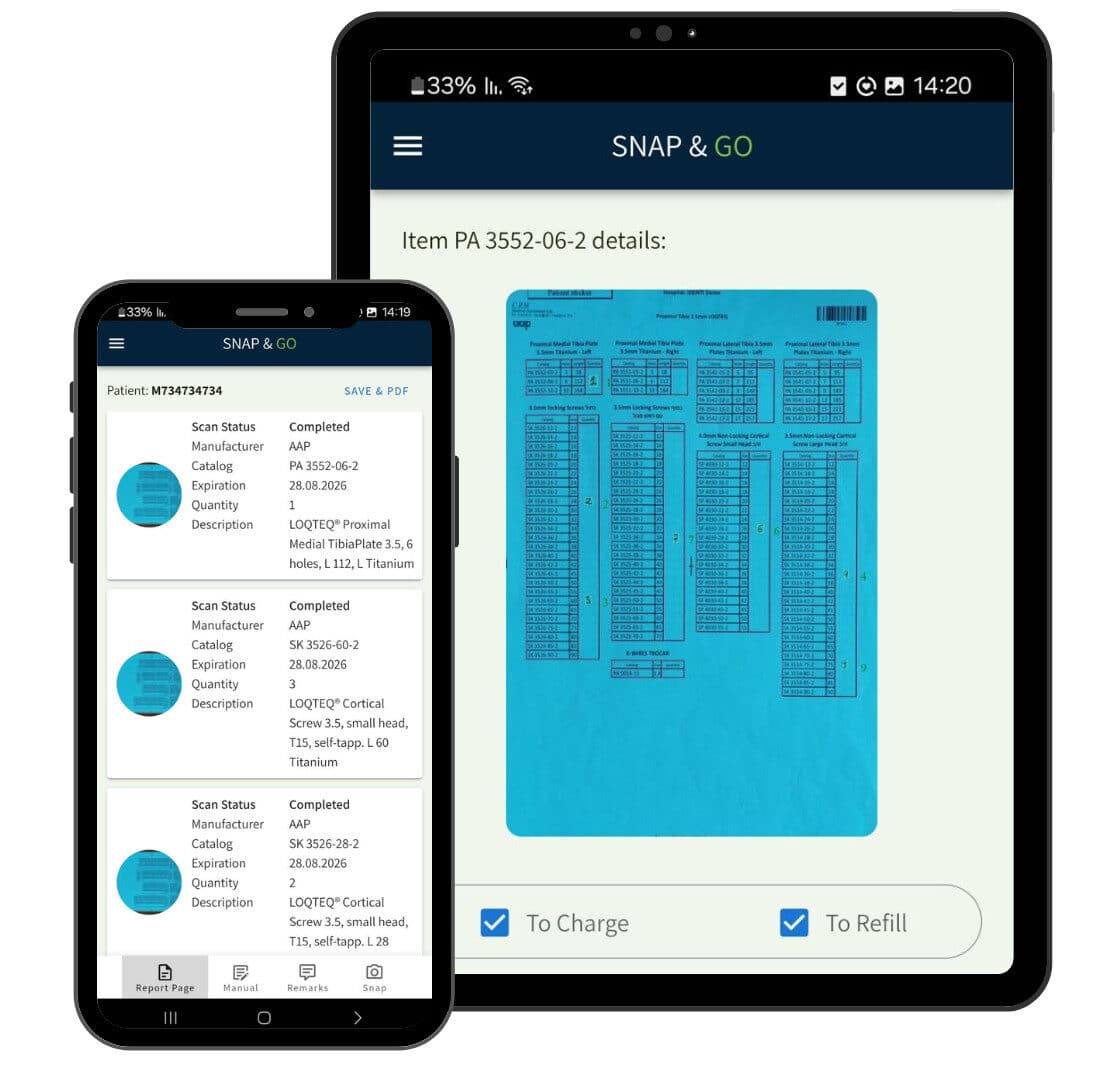

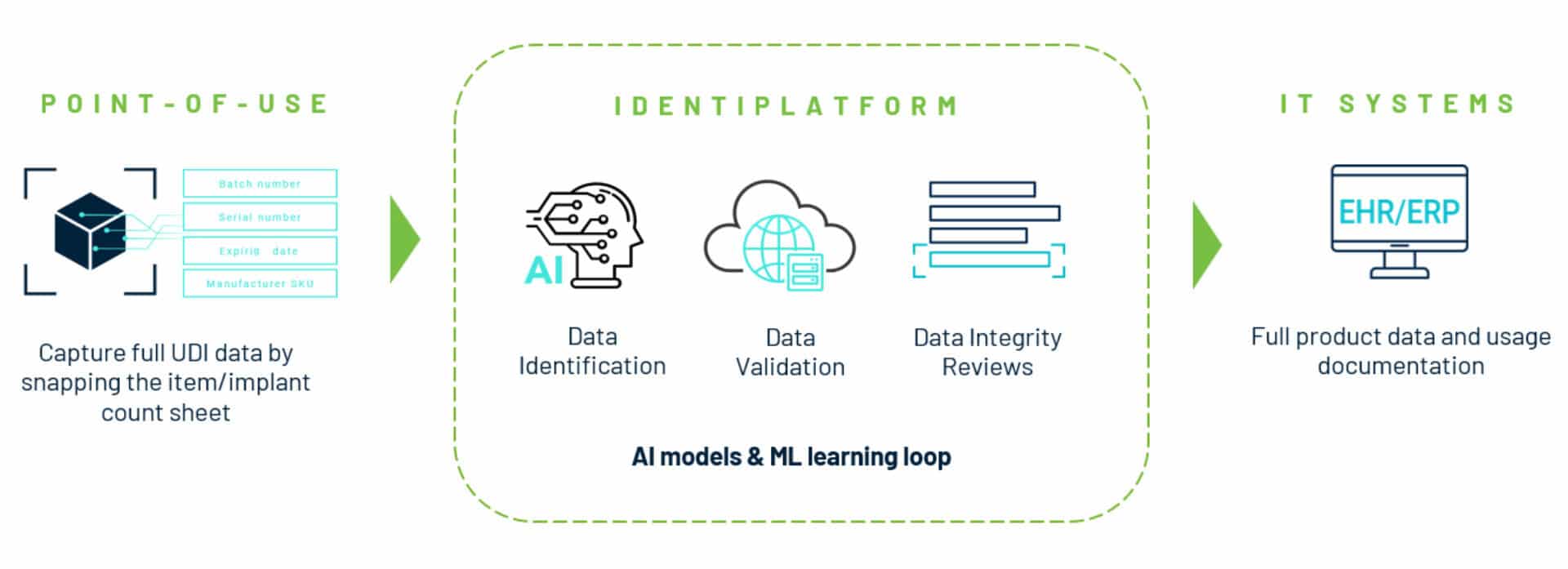

In a complex, high-cost orthopedic elbow surgery at a large hospital network in the US, Snap&Go, an AI-powered computer-vision camera, was benchmarked against standard perioperative documentation in a leading EHR.

The case, drawn from a regional academic network, was designed to evaluate AI computer vision for perioperative documentation in an expensive, implant-dense elbow procedure performed under routine conditions with manual implant count sheets. Inventory included both consignment and hospital-owned stock.

The objective was to compare documentation completeness, accuracy, and financial fidelity between the EHR workflow and Snap&Go in the same procedure, and to assess whether camera-based capture delivers materially better recording of implant and med-surg utilization, superior lot/expiry completeness, and clearer financial traceability.

Methodology: Evaluating Charge Capture Accuracy in Orthopedic Procedures

During routine documentation, the OR team used the EHR’s standard charge-capture tools (pick lists/barcode scans), implant logs, and charge rules.

In parallel, a designated RN team recorded all chargeable implants and consumables with the Snap&Go device positioned at the point of use.

Post-case analyses included: Line-item reconciliation, Catalog-level matching, Charge valuation, Data integrity, and completeness checks (lot and expiration capture).

Key Findings: Where Orthopedic Surgery Charge Capture Breaks Down

1. Bill‑Only high‑value implants and item‑master gap

Snap&Go captured 127.08% more chargeable value than the EHR, indicating material revenue exposure. The dominant driver was two Smith & Nephew EVOS plates – $900 each – recorded only by Snap&Go and corroborated by a vendor count-sheet completed by the OR team and imaged by the Snap&Go camera.

These implants, approximately 60% of the case value, were bill-only items. With no manufacturer catalog number onboarded in the EHR item master, they were not selectable and therefore not billed. The missed charges total $1,800.

Notably, several days post-op, the items still had not been added to the EHR record, a significant reconciliation/governance red flag.

2. EHR Misdocumentation and item value gap

The EHR contained two misdocumented items; the assumption is that human error was involved (wrong selection/SKU errors), which undermines claim accuracy and may impact the ability to obtain full reimbursement.

The size captured in the Snap&Go reflects a 15% higher item value. Snap&Go provided corroborating evidence – a handwritten vendor count-sheet image and a time-stamped device record – which indicates that this mismatch in the EHR documentation could potentially undermine claim accuracy and the hospital’s claim credibility.

3. Med-surg under-documentation

Med-surg consumables, such as skin staplers, Ioban, NaCl irrigation, and an irrigation set, representing approximately 18-21% of this case’s value, were missing from the EHR record.

Root causes include reliance on manual pick lists/barcode scans and implant-centric preference cards, while these items are typically stocked via SPD/distributor channels rather than vendor implant trays.

In contrast, Snap&Go captured these lines consistently at the point of use, with complete lot/expiry where applicable, closing the transparency gap and enabling accurate, actual-use case costing, improved costing fidelity, and reduced charge variability.

4. Data completeness gap

To audit the integrity of item data, we defined completeness as having both lot/batch and expiration fields populated for each item. Snap&Go recorded these identifiers on nearly 100% of captured items, with image-backed label evidence at the point of use. In contrast, the EHR export included lot/expiry on only 10.5% of items, leaving most entries blank, consistent with manual pick/scan workflows and implant-centric preference cards.

This completeness gap directly affects UDI traceability, recall readiness, audit defensibility, shelf-life management, and cost–charge reconciliation, with Snap&Go providing the materially stronger data trail.

Conclusion: Strengthening Orthopedic Surgery Charge Capture and Revenue Integrity

In this complex elbow case, AI computer vision documented more of what matters than the EHR, including high-value implants that were bill-only and not yet onboarded in the item master, complete lot/expiry identifiers, and med-surg consumables that manual workflows often miss.

The result is stronger orthopedic surgery charge capture, cleaner and more defensible claims, better UDI/recall traceability, and truer procedure-level costing.

The gaps trace to item-master setup deficiencies, the inherent difficulty of bill-only capture (non-onboarded SKUs aren’t selectable), manual pick/scan friction, and consignment onboarding delays. The evidence speaks for itself.

Interested in learning how IDENTI’s computer vision technology transforms orthopedic surgery charge capture and revenue reconciliation?

Contact us today and download the full case study here.