What’s inside:

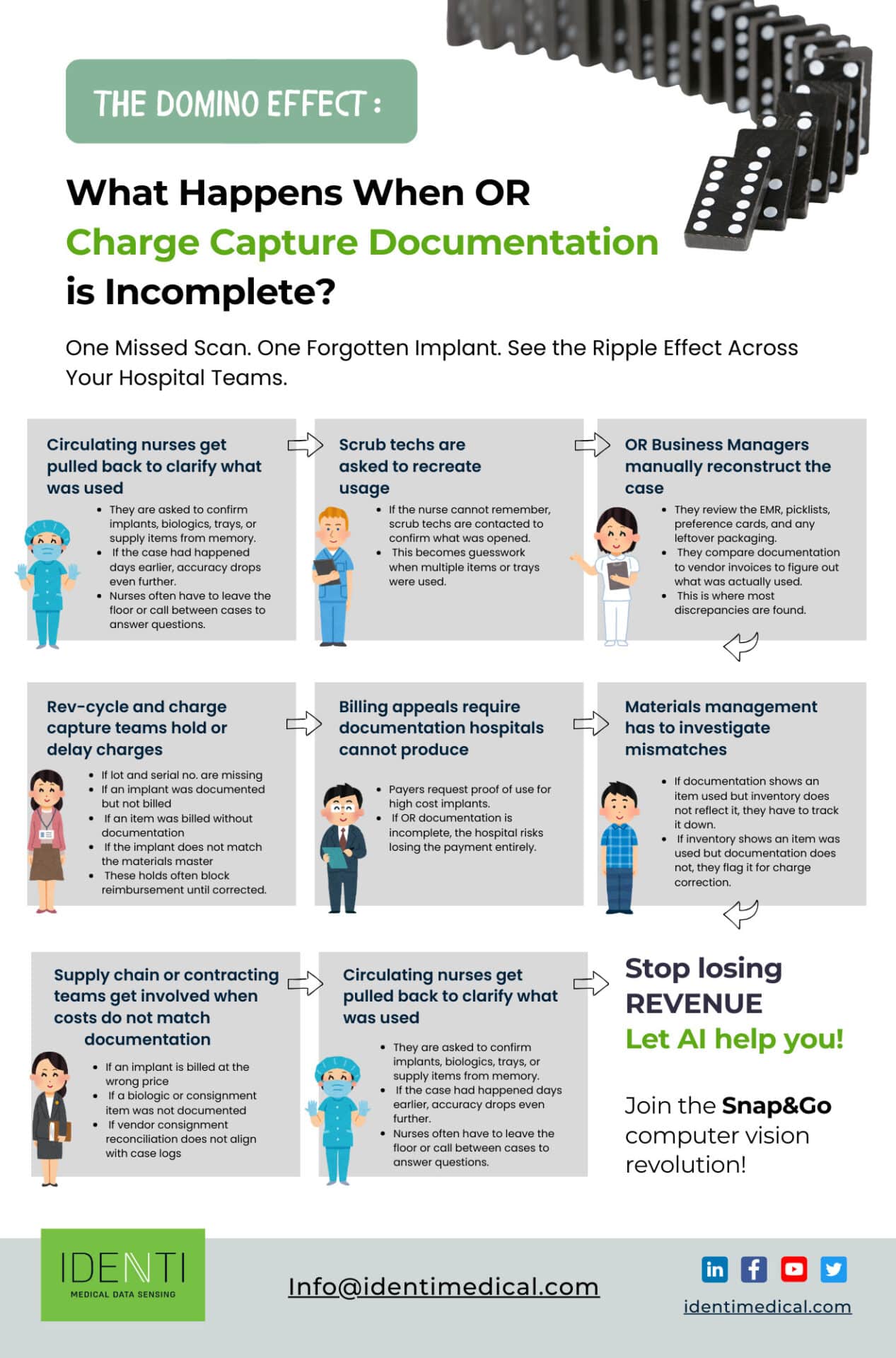

A clear visual breakdown of how one missed scan or undocumented implant in the OR triggers a chain reaction across hospital teams, business office, supply chain, and revenue cycle, leading to lost revenue, delays, and hours of manual reconstruction.

Operating rooms across the U.S. and worldwide face a shared challenge: incomplete or inaccurate OR charge capture documentation. Even a single missed scan or forgotten implant can create a ripple effect that impacts nurses, scrub techs, perioperative business teams, materials management, supply chain, and revenue cycle teams.

When OR charge capture documentation doesn’t reflect what was actually used, hospitals face:

- Revenue leakage

- Delayed charges

- Denied claims

- Massive reconciliation workload

- Nurse and scrub tech interruptions

- Inventory inaccuracies

- Vendor mismatches

To show the real impact of a documentation gap, this infographic illustrates the domino effect inside hospitals when OR documentation isn’t complete or accurate, and how automated charge capture prevents it from the start.

What Really Happens When There is Incomplete OR Charge Capture Documentation?

1. Circulating Nurses Get Pulled Back to Clarify OR Charge Capture Documentation

When documentation is missing or unclear, circulating nurses are the first to be contacted. They are asked to confirm:

- Which implants were used

- Whether biologics, trays, or supply items were opened

- Any items that may have been discarded

They are asked to recall from memory. And if the case happened days earlier, accuracy drops significantly. Nurses often must:

- Leave the floor

- Call between cases

- Rely on memory

This reduces OR efficiency and contributes to nurse fatigue.

2. Scrub Techs Are Asked to Recreate the Case for Documentation Accuracy

If nurses cannot recall specifics, scrub techs are pulled in to help rebuild the case and confirm what was opened.

They may be asked:

- What implants were opened

- Which trays were used

- Which biologics came into the field

This becomes guesswork when:

- Multiple sets were opened

- Implants were swapped mid-case

- Packaging is no longer available

This is a major source of downstream documentation errors.

3. OR Business Managers Manually Rebuild OR Charge Capture Documentation

Managers review and piece information together from:

- EMR records

- Picklists

- Preference cards

- Any leftover packaging

- Vendor invoices

They compare documentation to vendor invoices to figure out what was used.

This is where most discrepancies are exposed:

- Missing lot/serial numbers

- Implants documented but not billed

- Items billed but not documented

- Incorrect implant matched to the materials master

This manual reconstruction often takes hours.

4. Revenue Cycle Teams Hold or Delay Charges Due to Documentation Gaps

Revenue cycle teams must place holds when:

- Serial or lot numbers are missing

- An implant was used, but not documented

- Documentation and billing do not match

- The item does not align with the hospital’s materials master

These holds frequently block reimbursement completely, especially for high-cost implants.

5. Billing Appeals Become Difficult Without Correct OR Charge Capture Documentation

Payers often request:

- Proof of implant use

- Documentation confirming high-value items

When documentation is incomplete, hospitals risk:

- Claim denials

- Extended appeals

- Losing the entire payment

Failures at this step can affect millions in revenue annually.

6. Materials Management Must Investigate Documentation and Inventory Mismatches

Materials management teams are tasked with reconciling:

- Documentation vs. inventory

- Inventory vs. vendor invoices

- Usage logs vs. consignment reports

Examples of mismatches include:

- Documentation shows an item used, but the inventory does not match

- Inventory shows depletion, but documentation does not

- Consignment counts do not match case logs

This step alone consumes a huge amount of operational time.

7. Supply Chain and Contracting Step In When Costs Don’t Match Documentation

When billing and case logs conflict with vendor invoices, the supply chain team must investigate:

- Incorrectly priced implants

- Undocumented biologics

- Consignment mismatches

These delays affect vendor relations, contract compliance, and audit readiness.

How IDENTI Snap&Go AI Prevents the Domino Effect Entirely

IDENTI Snap&Go uses AI-powered computer vision to automatically capture implants, trays, biologics, and supplies at the point of use in the OR, eliminating manual scans and guesswork. This creates a complete digital trail of product usage and ensures documentation is accurate from the very start.

With complete and accurate OR charge capture documentation from the start, Snap&Go delivers:

- No more manual reconstruction

- No interruptions to clinical teams

- No more delayed charges

- No more payer denials

- No more inventory mismatches

One scan, zero guesswork. 100% accurate OR documentation.

This is More Than a Documentation Problem

When there is incomplete OR charge capture documentation, your highest-value clinical staff are pulled into administrative roles, your revenue cycle becomes strained, and your ability to get paid is compromised.

Fixing documentation at the source eliminates:

- Revenue leakage

- Avoidable labor costs

- Clinician burnout

- Denials risk

- Supply chain inefficiencies

IDENTI Snap&Go ensures accuracy at the point of use before the domino effect starts.

Download the infographic here and schedule a demo to learn more.